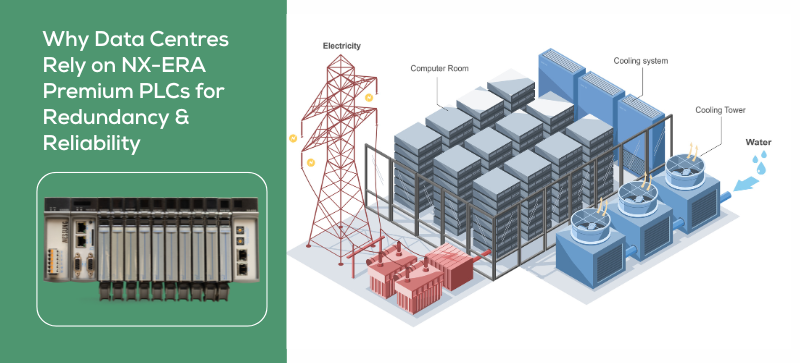

Data centres are the online headquarters of businesses today. Every click, transaction, login, or query is responded to via a data centre. In this hyper-connected world, downtime is more than a slowdown; it’s a disaster.

Whether it is hosting cloud applications, running finance systems, or managing mission-critical enterprise data, data centres simply can’t afford failure of control. That’s why businesses often spend money on layers of redundancy, not merely power or cooling, but even on the thinking brain of their infrastructure: the Programmable Logic Controller (PLC).

This is where Messung Industrial Automation’s NX-ERA Premium PLCs come in as a strategic benefit, designed to provide unparalleled modular scalability, PLC redundancy, and seamless SCADA integration for control that’s future-proof.

The Challenge: When Control Systems Become the Weak Link

Power? Backed up. Cooling? Redundant. However, what about the control systems controlling these vital components?

Standard or mini PLCs lack the sophistication needed to handle the mission-critical data centres’ demand. One logic mistake or hardware malfunction can take down numerous systems, usually with SLA fines, reputation damage, and monetary loss.

What is required is a Premium PLC solution that guarantees:

- High-speed, deterministic control

- Hardware and logic level redundancy

- Modern SCADA and BMS integration

Scalability as the data centre grows

The Solution: NX-ERA Premium PLCs, Control that Never Sleeps

Built to provide dependable, high-availability automation, our NX-ERA provides much more than your average PLC controller. Let’s break down what makes NX-ERA the top choice for data centre automation:

1. Built with Redundancy: Always On, Always Watching

Designed with a redundant PLC, NX-ERA runs on two CPUs – one primary and one hot-standby. They are mirroring each other in real time. If the main unit fails because of power problems, software glitches, or hardware malfunction, the standby takes over immediately, with no downtime. This degree of PLC redundancy is mission-critical to sustain:

- Continuous HVAC and precision cooling

- Real-time UPS and power distribution management

- Live fire detection and suppression procedures

- 2. Integrated High-Speed PLC Performance

NX-ERA is a high-speed PLC with processing power for complex, distributed systems. With event sequencing, real-time I/O update, and determinism support, it ensures that each action is done with precision and accuracy. It’s like having a control system that can anticipate trouble before it occurs.

3. Modular PLC architecture for changing infrastructure

In contrast to fixed systems, our NX-ERA boasts a modular PLC design wherein you can introduce new elements, such as I/O racks, processors, or server room sensors, without having to reconfigure or replace the original configuration. This is necessary in contemporary data centres where growth is ongoing.

4. Centralised Command SCADA Integration

NX-ERA enables smooth SCADA integration via MODBUS TCP/IP and lets you:

- Monitor system health through central dashboards

- BMS and environmental management system integration

- Allow predictive maintenance and compliance monitoring

- Custom logic event-based fire alarms

This turns your PLC controller into the eyes and ears of your operation, reporting, responding, and recording in real time.

NX-ERA in Action: Where It Delivers Inside a Data Centre

Contemporary data centres are precision ecosystems. Every subsystem, power, cooling, and fire protection, has to work in a very sophisticated unison. And NX-ERA Premium PLCs are the invisible heroes, directing all the elements to work together in precision, in complete synchrony and faultlessly.

Let’s observe how NX-ERA extends operational excellence to the most critical automation domains:

- Precision Environmental & Cooling Management

Maintaining the right temperature and humidity is not just about extending equipment life; it’s about performance reliability and data integrity. Any slight discrepancy can cause server throttling, random shutdown, or damage due to condensation. NX-ERA exercises close control over:

- CRAC units and air handlers: Thermal hotspots are averted by continuous feedback loops and high-speed actuation.

- Chilled water distribution and airflow systems: Adaptive logic keeps cooling in phase with current server loads.

- Humidity control: Essential in helping prevent electrostatic discharge and hardware long-term health.

What is special about NX-ERA in this regard is that it can perform environmental control logic with microsecond accuracy, supplemented with real-time data monitoring and logging for auditing, regulatory compliance, and AI-driven optimisation.

2. UPS Control & Power Synchronisation

Uninterruptible Power Supply (UPS) systems are only as good as the logic behind them. Our NX-ERA functions as a moderator, synchronizing among multiple PDUs, UPS systems, and switchgear units. It ensures:

- Seamless power source transitions during outages or load fluctuations

- Real-time load balancing to avoid overloads and maintain energy efficiency

- Phase synchronization for harmonized energy supply between server halls

Where basic PLCs can lag or lose a beat during transitions, NX-ERA’s high-speed PLC architecture anticipates power shifts and actively synchronises systems to absorb the impact, critical in Tier III and Tier IV data centres where downtime is not an option.

3. Fire Detection & Suppression Integration

When safety is not negotiable, response time is paramount. NX-ERA has real-time fire detection integration with intelligent logic chains that coordinate:

- Smoke, temperature, and gas detector sensor integration

- Alarm signalling through audio-visual signals

- Release logic for chemical or inert gas extinguishing agents

But here’s the surprise: NX-ERA performs these life-safety functions without affecting other automation tasks. Fire suppression systems may initiate in one area, yet cooling, power, and access control systems continue uninterrupted in other zones.

4. Shutdown-Free Maintenance: Redundancy in Action

All PLC systems will eventually need maintenance, but taking down operations to make it happen? That’s a luxury no contemporary data centre can afford. NX-ERA avoids this inconvenience with live-switching redundancy:

- You can upgrade firmware, replace I/O modules, or perform diagnostics on the main PLC.

- In the meantime, the secondary PLC continues the automation uninterrupted.

- After maintenance is finished, the jobs reverse, without any effect on operations.

This is redundancy in practice, not on paper, but in everyday ops. It’s the way Redundant PLC logic makes scheduled downtime a non-event.

Business Benefits Over Engineering Specs

NX-ERA is more than just an upgrade to technology; it is an enabler for business. Here is how it immediately impacts operational and financial KPIs:

- Uptime Confidence: Meets even the strictest SLAs with real-world dependability, minimising risk of penalties and guaranteeing service continuity.

- Cost Efficiency: Avoids the enormous cost of downtime—lost business, manual intervention, and recovery of the system—and optimises energy usage with intelligent logic.

- Compliance-Ready: With NX-ERA’s thorough logging, audit trails, and snapshots of environmental data, ISO, ASHRAE, and Tier certifications are simple to comply with.

- Future-Proofing: Built with Industry 4.0 PLC capabilities, such as remote access PLC capabilities, analytics, and diagnostics that become increasingly smarter with your infrastructure.

This is intelligent automation systems delivering tangible return on investment, not in years, but in months.

The Road Ahead: Industry 4.0 Compliant, Future-Ready

NX-ERA is designed for the future by predicting the needs of tomorrow’s data centre architecture today.

- Designed for Edge computing applications where distributed processing is paramount

- Smart analytics tools that are AI-enabled, performance optimisation compliant

- Remote diagnostics and control, allowing for predictive maintenance anywhere

- Integrates perfectly with AI-based decision systems, positioning your business for the next decade

As the business shifts towards smart control systems, NX-ERA is leading the way—not just prepared but already ahead.

Conclusion: Trust NX-ERA for Control that Never Compromises

Trust drives data centres. Trust that each byte is secure. Trust that there’s uninterrupted uptime. Trust that operations persist, no matter what. NX-ERA Premium PLCs are designed for this trust.

Where time matters, every control logic matters. And that’s where NX-ERA sets the pace: redundant PLCs, real-time SCADA integration, and modular PLC architecture for the intricacies of the future. We don’t merely create control systems at Messung Industrial Automation. We create trust.

FAQs

- In what way is NX-ERA different from standard PLC controllers?

NX-ERA is a High-availability Premium PLC that is suitable for high-availability environments. It accommodates redundant configurations, modular scalability, and advanced SCADA integration, as opposed to basic or micro-PLCs.

2. What is the method of NX-ERA’s PLC redundancy?

NX-ERA has dual CPUs (main and standby). If the main fails, the standby takes over at once, with zero downtime or loss of data.

3. Is NX-ERA compatible with the current data centre infrastructure?

Yes. With MODBUS TCP/IP and SCADA-ready capabilities, NX-ERA is easily compatible with all control systems and BMS.

4. Is NX-ERA able to support small and large-scale data centres?

In fact. Its modular PLC design allows for effortless scaling, from small server rooms to multi-hall Tier IV data centres.

5. Does NX-ERA support Industry 4.0 PLC features?

Yes, it also has remote access, diagnosis, data logging, and intelligent analytics capabilities, and therefore is fully Industry 4.0-compatible.