MESSUNG AND THE EVOLUTION OF THE PLC SYSTEM IN INDIA

For almost four decades, Messung has been at the forefront of industrial automation in India. Recognised as the pioneer of the first indigenous PLC in India, Messung has consistently innovated PLC and allied products for industrial automation since its start in 1981.

Today, four decades down the road, Messung is a leading Technology expert in India, still driven by pioneering zeal, a passion for new ideas and pursuit for excellence to bring progressive solutions that deliver the competitive edge for customers.

Messung empowers businesses and industries with the foremost technologies and high-performance products backed by deep domain knowledge and reliable support.

Let’s understand what is PLC system, and go down memory lane with Messung to trace the evolution of programmable logic controller technology in India.

ABOUT PROGRAMMABLE LOGIC CONTROLLER

PLC stands for Programmable Logic Controller. The programmable controller is a specialised industrial computer that has been adapted for the control of manufacturing processes, such as assembly lines, machines, robotic devices, or any activity that requires high reliability, ease of programming, and process fault diagnosis.

The PLC control unit continuously monitors and automatically controls the different processesand components in an industrial system, gets them to function together as a well-coordinated unit, and makes decisions based on a custom programme.

Besides industrial process and machine automation, you will also find the PLC in electrical engineering where it powers modern power distribution and energy management solutions.

HOW PLCs WORK

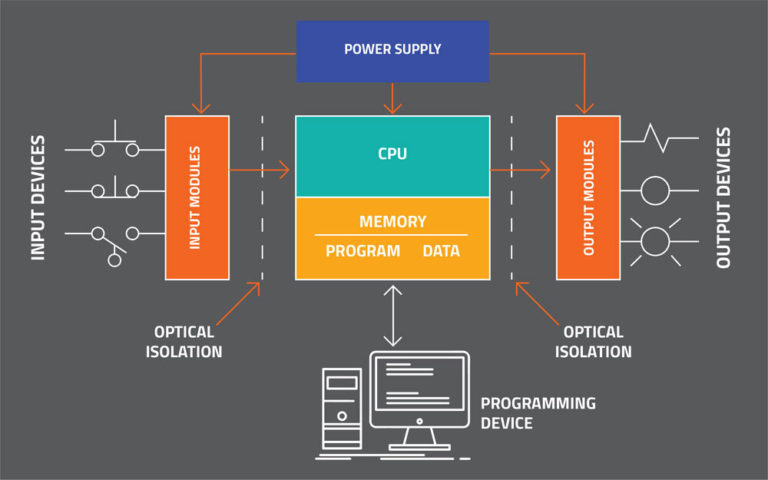

PLCs come in different shapes and sizes but all of them consist of four core sections:

- The central processing unit

- The power supply

- The input/output (I/O) section

- The program section

PLC system layout

Basic function of PLC is to capture data from the plant floor by monitoring inputs from connected devices and machines. The input data is then processed by the CPU which applies logic to the data. The CPU executes the user-created program logic and outputs data or commands to the devices and machines it is connected to.

PLC programming can be done in several ways, from ladder logic, which is based on electromechanical relays, to specially adapted programming languages of BASIC and C, to name a few. Most PLC control systems today use one of the following 5 industrial automation programming languages: Ladder Diagram, Structured Text, Function Block Diagram, Instruction List, or Sequential Function Charts.

PLC’s act as the physical interfaces between devices on the manufacturing floor and a SCADA or HMI system. (SCADA full form: Supervisory control and data acquisition)SCADA and HMI systems enable users to view data from the manufacturing floor and provide an interface for users to provide control input.

Now that we have an introduction to PLC and how PLC works, let’s go back in time to the period when Messung pioneered India’s first indigenous PLC.

1981-1990 THE ADVENT & EVOLUTION OF THE PLC

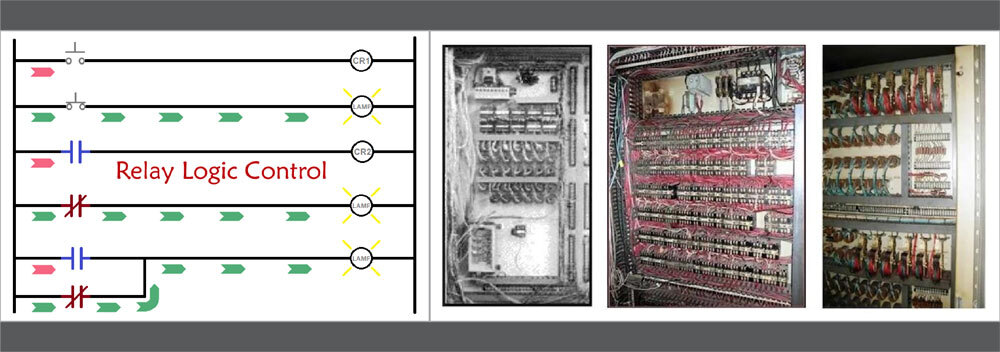

In those early days, automation of industrial machinery was usually done using electro-mechanical contactors that created logical interactions by using the NC/NO contacts and electrical wiring to achieve logical decisions and interlocks. There were no PLC manufacturers in India to give solutions to machine manufacturers.

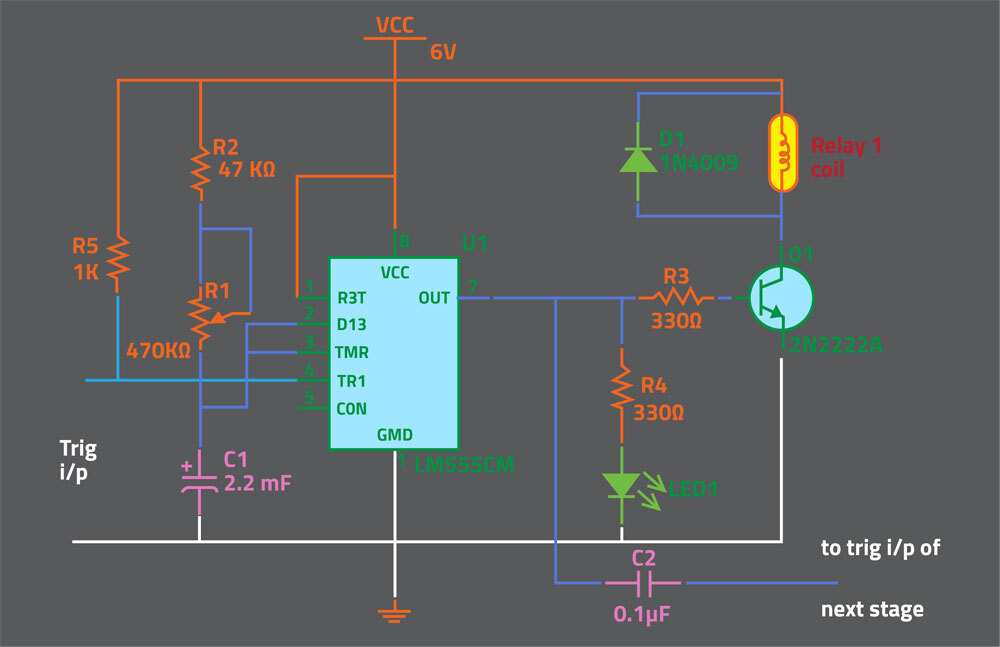

In the 1980s, the first few varieties of PLCs were launched. The early PLCs had a minimum “set of instruction”, and mainly covered logical functions like ‘And’ ‘Or’ ‘store output’ ‘load’ and ‘complement’ functions that were used to create simple ladder diagrams which were easy to understand by electrical control engineers.

In the mid-80s, microprocessor-based PLCs were developed, based on the Zilog-80 and Intel micro-processor based eight-bit technology. The simple ‘instruction set’ now had ‘word’ functions including ‘move’, ‘compare’, ‘greater than’, ‘less than’ along with simple mathematics, software timers; counters were possible.

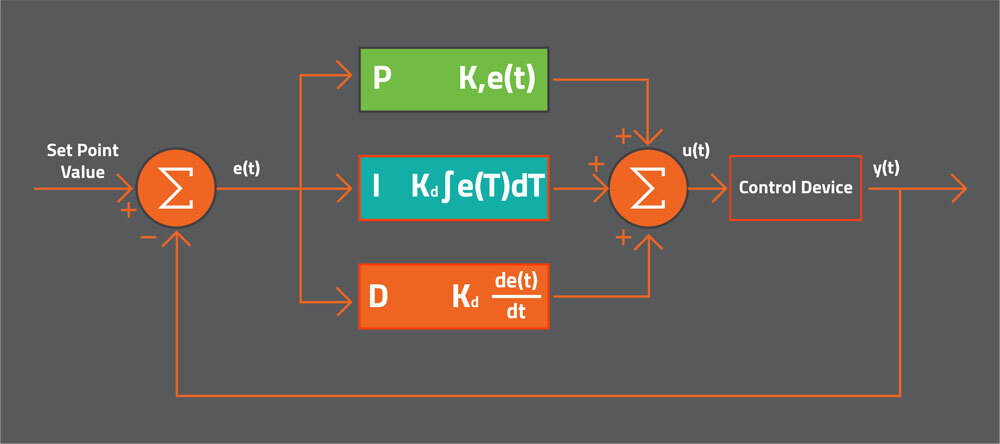

One could also achieve functionalities like simple PID controls, replace ‘Drum wheel’ controllers, Sequence timer functions. More complex automation applications could be done with proper automation functions and interlocks including Arithmetic calculations e.g.

- Electroplating plants

- Painting lines

- Sugar Centrifuge

- Boiler and Heat treatment applications

MESSUNG: FOUR DECADES OF TECHNOLOGY DEVELOPMENT

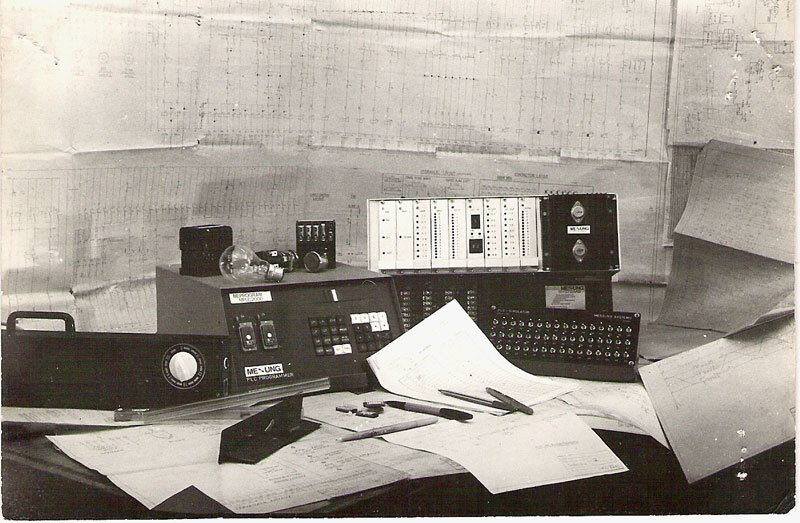

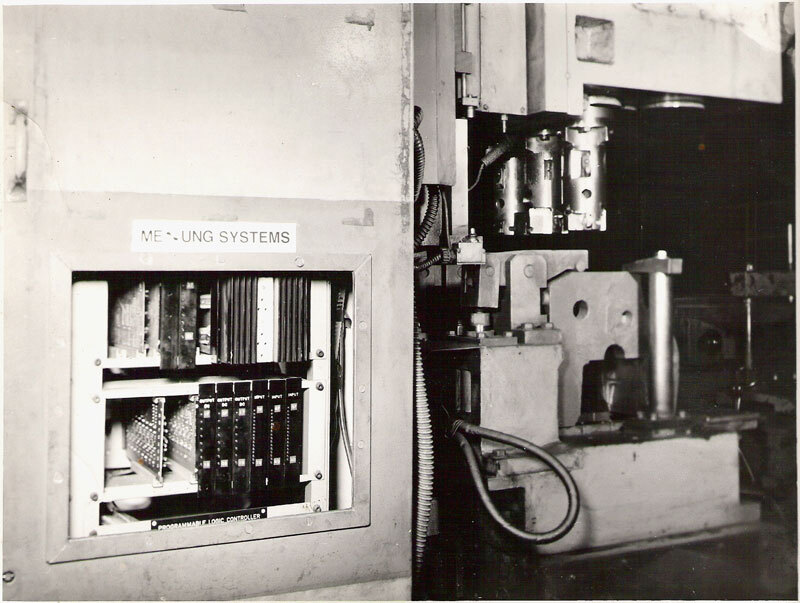

In 1981, Messung was founded, and began developing a prototype Programmable Logic Controller (PLC) in a humble garage. Within a couple of years, Messung launched Meprolog-H, India’s first indigenous PLC and in 1984, installed the first one at Kirloskar Oil Engines, Pune.

In 1986, Meprolog-H won the G.S.Parkhe Award and FIE Foundation Award for Best Product Design, and in 1988, Farook Merchant, the founder of Messung, received the National Award for Outstanding Entrepreneur. The following year, Messung launched XMP8-40*, the first 8-bit microprocessor-based PLC which went on to achieve 6000 installations.

The following decade saw Messung continue on its journey of indigenous innovation. In 1992, XMP8-20* PLC was designed for smaller, compact machines, and installed in 12000 projects. Three years later, XMP8-10*, the ‘small wonder’ was launched and used in 25000 installations.

In 1996, Messung won the International WISITEX Award and Award for Excellence in Electronics by Govt. of India – achievements that only fuelled Messung’s passion for innovation. In 1998, NEXGEN 4000* PLC was designed in modular structure – and went on to win the FIE Award for Best Product Design.

In 2001, the NEXGEN 5000* PLC based on IEC 61131-3 standards was developed and in 2008, the NEXTO* PLC was developed. The next year, NEXGENIE*PLC was launched.

In 2017, Messung launched the advanced NX-ERA series of PLCs for Industrial Automation. The Series of PLC controllers includes the modular NX-ERA Premium, and the NX-ERA Xpress developed indigenously by Messung (as per IEC 61131 programming standard). NX-ERA Xpress is a famous PLC offering advanced features in a compact footprint. NX-ERA Xpress is the best PLC for entry-level applications.

With the NX-ERA series of PLCs, and its own indigenous XM-PRO series of Remote I/Os, VFDs and servo drives, HMIs and SCADA applications, Messung develops customised industrial automation solutions for diverse applications. Automotive PLC systems, automatic water distribution systems, PLC bottle filling system, PLC based sorting system, boiler PLC control system, HVAC PLC control systems and an infinite number of PLC control systems for diverse process and machine automation applications.

Messung is committed to enabling enterprises large and small, to harness the advantages of PLC technology and IoT-enabled, integrated industrial automation – to achieve the leading edge.

* All products mentioned before 2012 are now the Intellectual Property of Mitsubishi Electric India Private Limited