CUSTOMISED PLC CONTROL PANELS

Any industrial, manufacturing, or production process application that requires flexible, reliable, and affordable automation control needs a PLC control panel (PLC full form is Programmable Logic Controller). Also known as PLC Automation Panels, these control panels offer an edge over conventional relay-based systems with their reduced size, ease in modification of logic, means of remote communications and advances in technology.

(For readers who want to know what is PLC and how does it work, PLC parts and what PLC is used in – we have written about PLC in our blog titled ‘What is a PLC?’. To know all about PLC, you may refer to it at your convenience.)

PLC panels are used in variety of electronic and electrical circuit fittings for a variety of applications which can be broadly divided into 3 categories:

OEM Control Panel: which covers applications such as wind turbine panels, compressor control panel, incinerators, boilers, chillers, spray driers, HVAC panels, etc.

Electrical Panels: covering MCC, PDB, Change-over panel, etc.

Instrumentation/Automation Panels: such as VFD panel, computer panel, monitor, pressurisation, SCADA systems.

ADVANTAGES OF PLC PANELS

PLC Panels are fast and flexible with easy to change logic. Due to the absence of moving parts, they are reliable and durable. The modular assembly makes maintenance easy.

PLC Panels are capable of handling complicated logic functions and offer facilities for diagnostics and fault finding. In the PLC panel, the counter, timer and comparator can be programmed, and one can expect good documentation facilities.

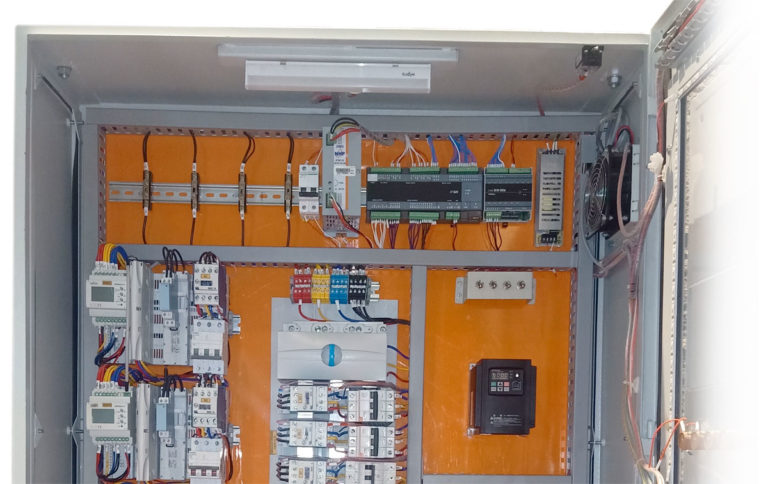

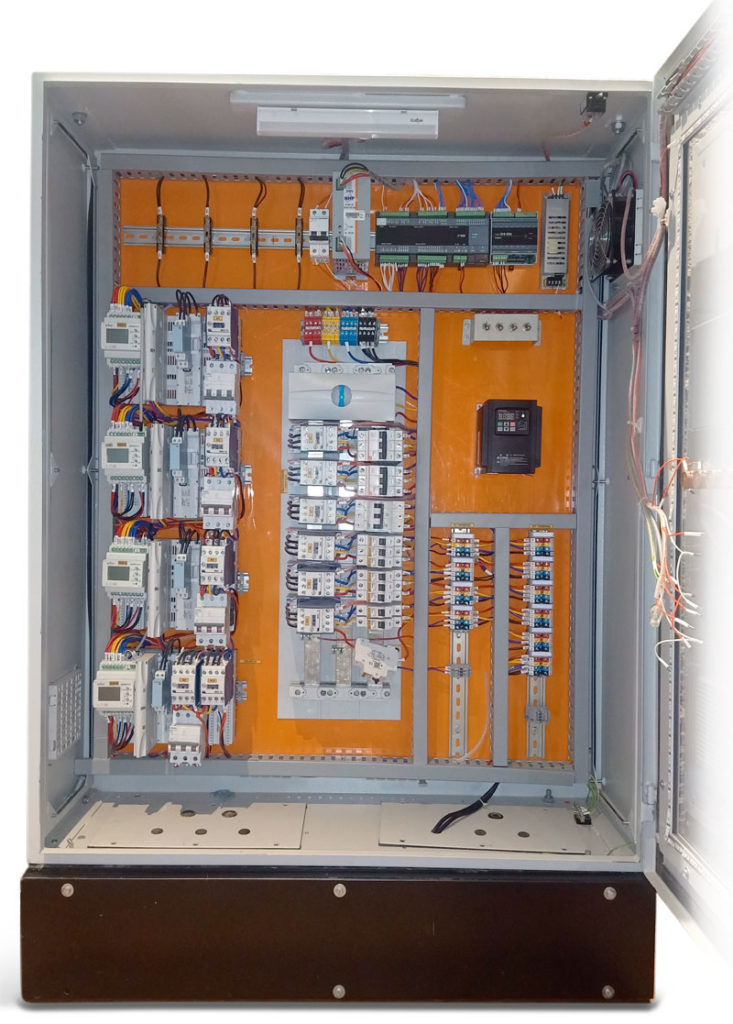

PLC CONTROL PANEL COMPONENTS

All PLC control systems include the panel structure and the internal components. Depending on the application and the user’s criteria, control panels are designed and fabricated.

For example, the structure of an industrial automation electrical PLC control panel is a combination of an enclosure, a back panel and doors (usually one or two depending on the size of the application). The enclosure usually comes with ratings that specify properties such as

- indoor/outdoor use

- water resistance

- explosion-proof rating

- hazardous conditions rating

- dust/contaminants proofing

There are 8 types of electrical control panel components which organise the different functions. These components include:

- Main circuit breaker

- Surge arrestors

- Transformers

- Terminal blocks

- Programmable Logic Controller

- Relays and contactors

- Network switches

- HMI (Human Machine Interface)

MESSUNG PLC CONTROL PANELS

Messung is one of India’s leading PLC manufacturers with decades of experience in designing PLC control panels and PLC programming for industrial automation.

Messung provides total solutions for all Automation projects and machines including supply of panels with complete switch gear and busbar solutions, user interfaces and cloud services.

Messung has a complete range of PLC products including specific ranges for the Process industry with high end CPUs and a complete range of inputs and outputs including ‘Hot’ standby and Redundancy. This PLC range also has all the international protocols built in, like Profibus, Ethernet TCP/IP, MQTT, OPC-UA, Hart, etc.

Based on these PLC products, Messung has developed a complete eco structure of products including good quality HMIs, encrypted and very reliable Cloud and IOT interfaces, SCADA, and many other third-party devices like surge suppressors, active harmonic filters and energy meters.

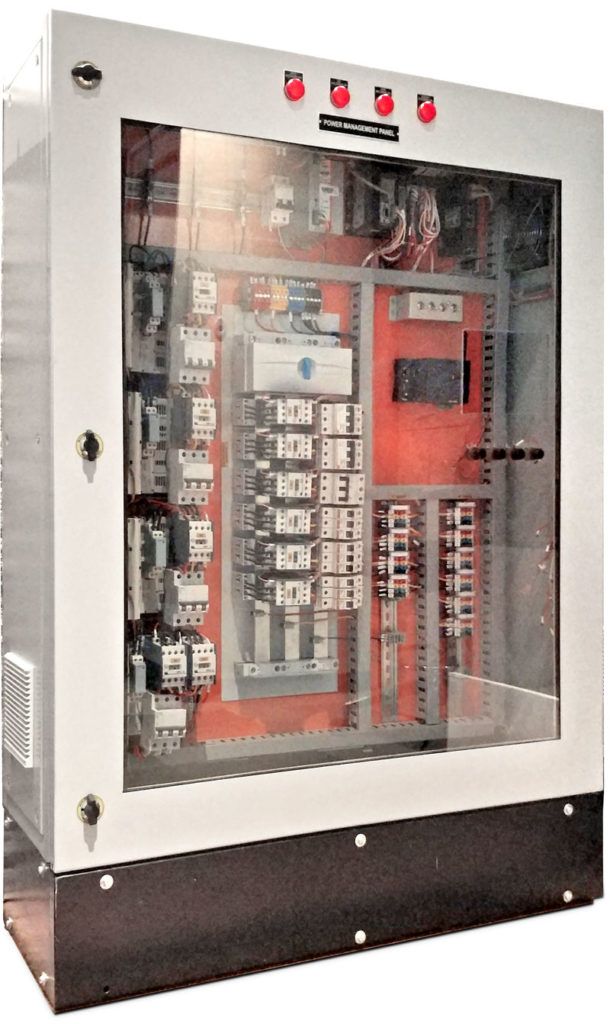

CUSTOM-BUILT INDUSTRIAL ELECTRICAL CONTROL PANELS FROM MESSUNG

In industrial automation, electrical panels play a crucial part. They provide higher-level monitoring and control of the various functions of production equipment, allowing manufacturers to define, organise and meet production objectives.

Depending upon the complexity of the system it is meant to operate, Messung designs custom “Control Panel Solutions” for a wide range of applications like water and waste water treatment plants, sugar machinery, plastic extrusion, printing, pharmaceutical, automotive assembly and testing lines, electro plating, boilers, material handling, furnaces, mechanical and hydraulic press and other similar applications in different industry verticals.

Messung makes these electrical panel solutions using their state-of-the-art fabricated MS or Aluminum panels and world class switch gears as per the standardization of the end user. Besides they also put in their NX-ERA PLC, Busbar products from Wöhner, international grade HMIs, energy meters and cloud interfaces. Every control panel and its components are as per the latest technologies. Using high-end design software, they are able to provide good quality documentation for easy and accurate maintenance and servicing.

PLUS POINTS OF MESSUNG'S CONTROL PANEL SOLUTIONS

- Design and development (Engineering) for electrical and instrumentation process control

- Manufacturing of all types of PLC & MCC Control Panels

- Availability of Factory Acceptance Test facility and commissioning service support at site

- On-time delivery of fully wired Control Panels

- Cost effective (affordable) solutions

Contact Messung with your PLC control panel requirements today.