process automation & control solutions in India

Smart Controller – A perfect fit for Every applications

Messung harnesses its decades of experience in industrial automation to custom design and manufacture Industrial Automation Solutions for varied equipment in diverse application areas.

Messung’s cutting-edge technology in PLC systems, Remote I/Os, enables high-performance, flexible machines that are information-enabled, and easy to integrate. They deliver real-timed diagnostics and maximise control, optimising safety, speed, productivity and efficiencies – for the competitive edge.

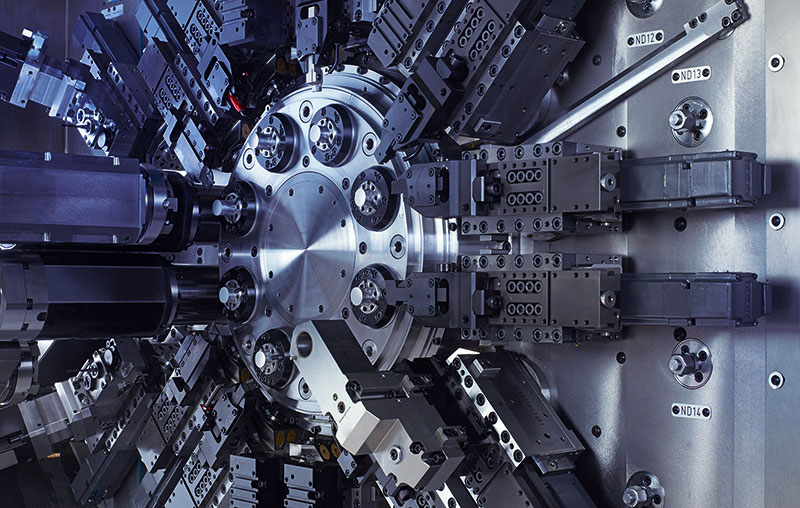

- SpecialPurpose Machines

-

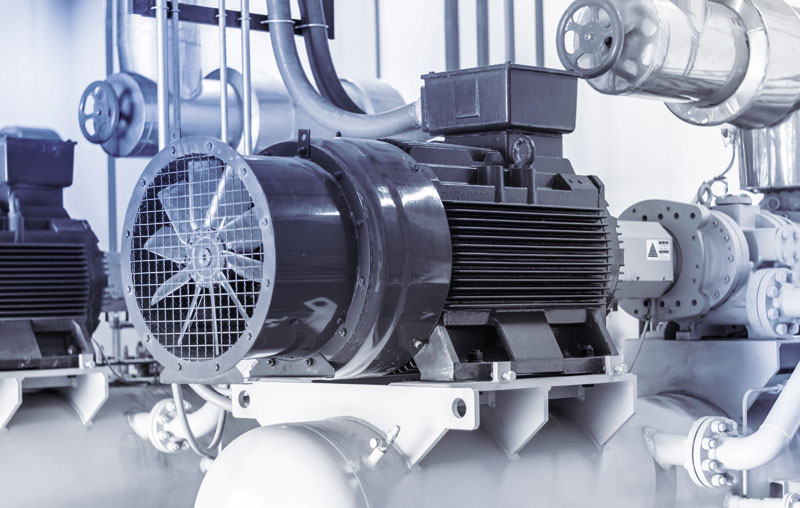

Utility

Applications -

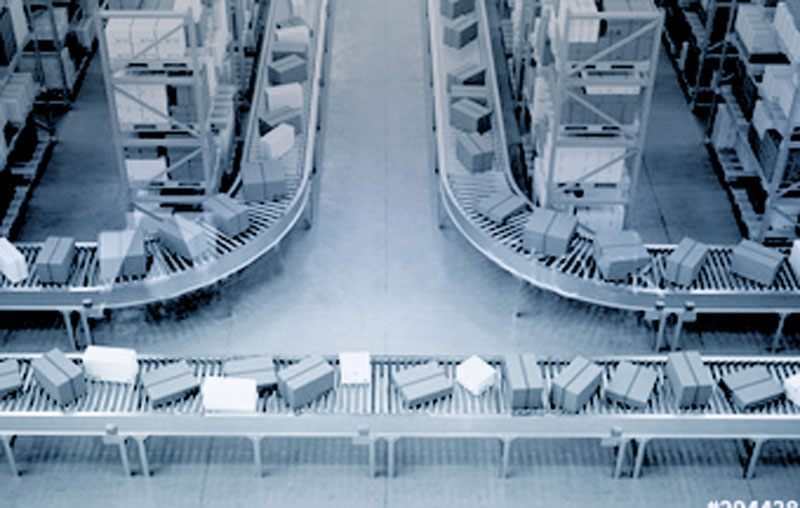

Material

Handling - Machineries ofGeneral Usage

- Packaging andFood Industry

-

Textile

Machinery -

Pharma

Industry

Every special purpose machine has its own specific requirements. It is therefore crucial that the right automation concept is used. Messung delivers tailor-made, cost-effective solutions based on Messung’s extensive know-how in automation and sector-specific experience.

Messung’s compact PLC control systems guarantee efficient, reliable and sustainable automation solutions for special purpose machine applications such as Hydraulic & Pneumatic, Indexing, Leak Testing & Multi-spindle Drilling Machines.

Modern utilities rely on automation to monitor and control their systems. They also depend on automatic systems to protect their network and investment.

Messung develops and delivers PLC systems that can be deployed in central utility plants for integration, remote monitoring and automated control of mechanical-electrical systems. As a result, users achieve greater reliability, visibility, energy savings and operational efficiency.

Useful for applications such as Compressor Control, Industrial Cooling Towers, Pump Management, Diesel Gensets and Industrial Chillers.

Material handling covers a wide range of equipment and systems in applications such as warehousing & distribution, airport baggage handling, manufacturing & bulk handling, postal & parcel delivery, etc. It is the overall taking care and control of materials, goods or products throughout the manufacturing process as well as distribution and disposal process.

Messung enables you to improve your operations with effective material handling control systems and information technology. We build robust and flexible automation systems with our strong PLC which can control all the mechanical systems and monitor all operating parameters.

Messung PLC plays a major role in applications such as Roller & Chain Conveyors, Manufacturing Distribution Systems, Powdered & Granular Solids, Pneumatic Transport System.

Today, enterprises are replacing labour-intensive manual operations that are prone to human errors, with automation control systems to improve productivity. Messung shapes solutions that are the right blend of hard and soft technologies needed to enhance performance, safety and control.

Our solutions deliver a flexible PLC system that is simple to operate and maintain, and can be installed for any General Purpose usage machines such as Press, Band Saw, Bale Press, Industrial Washing Machines, Ring Frame, etc.

High-performance, flexible automation is crucial in the Food & Packaging industry. The demands on Machines and Equipment are continously increasing. Continous changes demanded by customer vary from product to product requiring the control system to adapt flexibily to format changes for e.g. when Lot sizes change from small to large.

Thanks to the open system architecture, you can easily include production and packaging systems equipped with our automation systems in production lines. Vision systems, robots and Pick & Place units can be seamlessly integrated.

Industrial automation is technology’s helping hand to boost productivity in the Textile industry with processes that used to be done manually. This way, anything that could only be done by hand now has machines and software to help with more speed and accuracy, avoiding errors.

There are several types of machines used by the textile industry. Cotton gins clean the seeds and debris from raw cotton. Spinning machines convert raw fibers into threads and yarn. Looms weave thread and yarn into cloth.

Messung’s solution is based on standard components, which contain highly modern technology and guarantee higher performance, efficiency and improved quality of your machines and equipment. Idle times and rejects are minimized.

The pharmaceutical industry is one of the industries that is subject to the strictest regulatory requirements and standards. For this reason, quality assurance is seen as one of the most important criteria in the production processes of pharmaceutical companies.

The PLC control systems in pharmaceutical industry works with packaging machines, purified water systems,dehumidifier machines and air handling units. This control system consists of hardware, software and network components together with controlled functions and associated documentations.

High-Quality PLC systems in the pharmaceutical industry requires great know-how and longstanding expertise. Messung have this expertise because we have been supplying efficient PLCs for more than 4 decades.