Precision cutting defines the performance of continuous production lines across industries. Flying shear machines address this need by delivering accurate cut to length machine operations without interrupting material flow. Widely deployed in rolling mills, tube mills, and steel processing plants, it cuts bars, rods, tubes, or sheets to the required length as they move along the line, ensuring uninterrupted throughput and high productivity.

The process demands high-speed synchronization between conveyor motion and the cutting blade. At production speeds that often exceed hundreds of meters per minute, even the smallest delay in blade engagement can lead to length deviation, excess scrap, or accelerated wear of cutting components. Consistently achieving the required accuracy therefore pushes the limits of mechanical systems and highlights the importance of intelligent control.

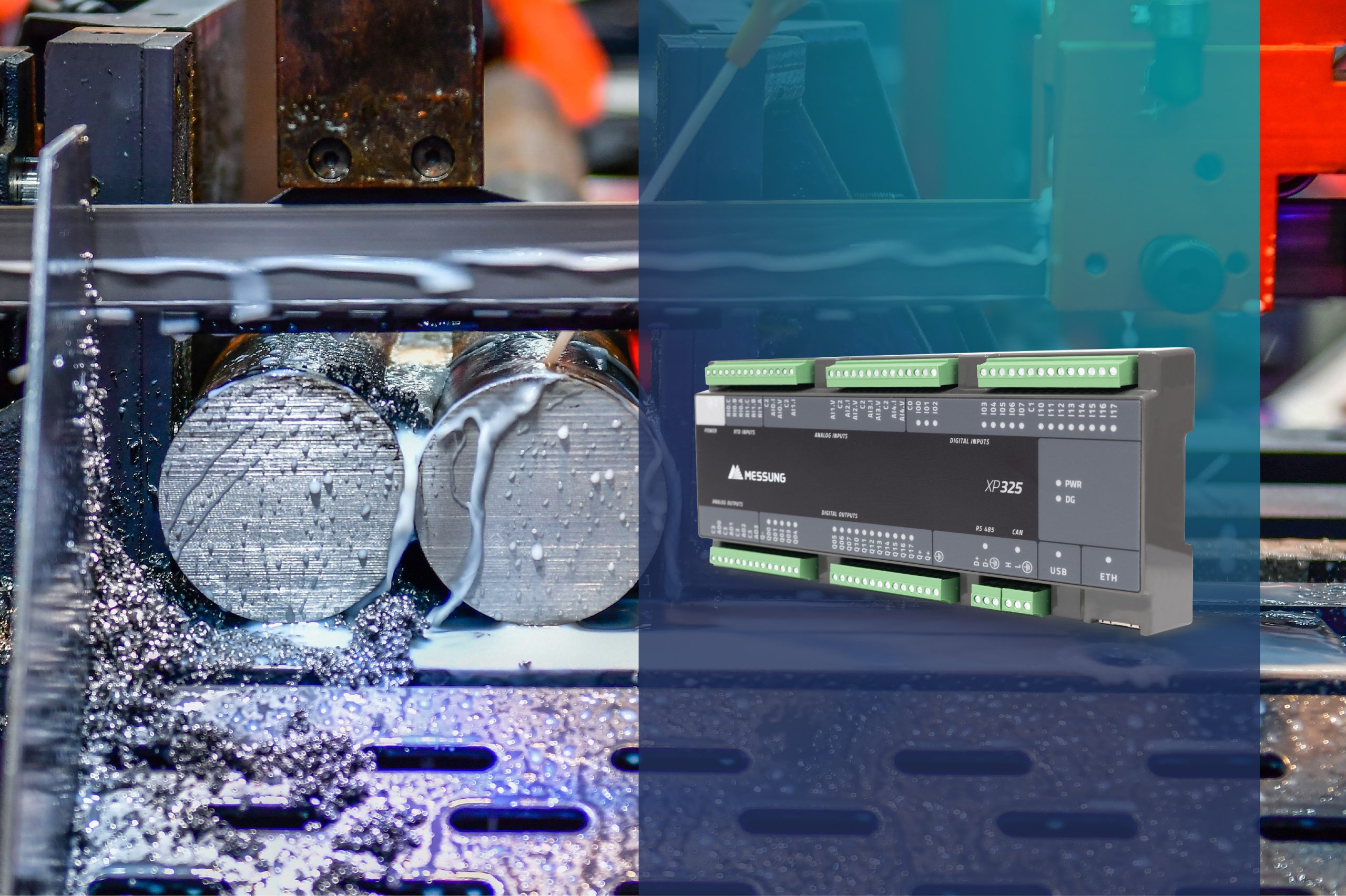

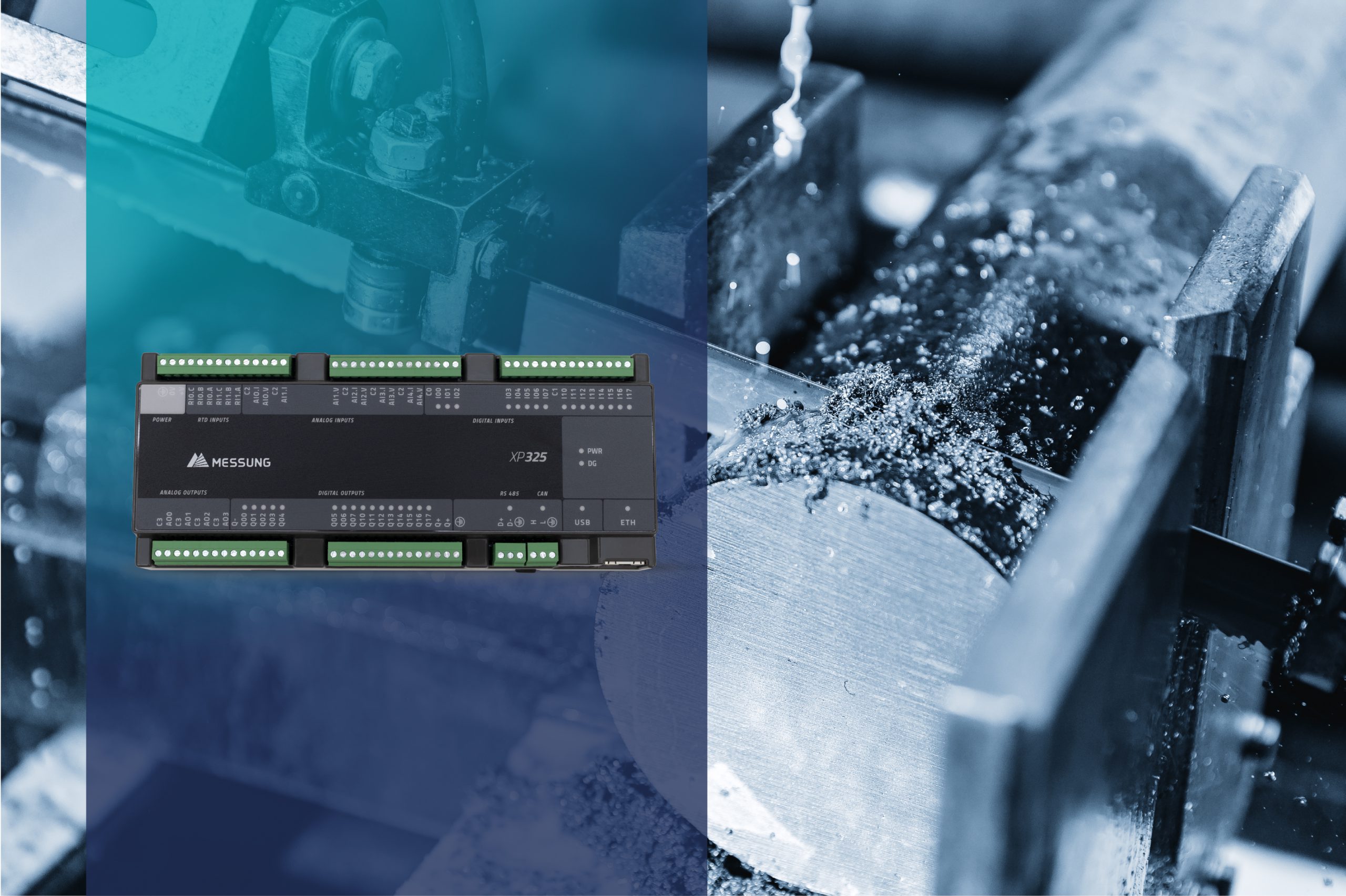

Modern PLC automation is essential for maintaining precision in high-speed cutting operations. By processing encoder signals in real time, a programmable logic controller adjusts blade timing to stay synchronized even with fluctuating line speeds. Messung’s NX-ERA Xpress PLC provides the speed and stability needed to reduce scrap, minimize mechanical wear, and ensure consistent cut-to-length accuracy while enabling higher throughput and reliable, Industry 4.0–ready production control

Challenges in Conventional Flying Shear Systems

- Mechanical synchronization prone to inaccuracies: Reliance on gears and linkages introduces backlash and lag, reducing cut-to-length accuracy and increasing scrap.

- Difficulty at high production speeds: Without encoder feedback or high-speed counters, conventional cut to length machines cannot maintain precision at variable line speeds.

- Higher wear and tear: Continuous mechanical stress accelerates fatigue of blades, couplings, and drive assemblies, leading to frequent maintenance and downtime.

- Limited control flexibility and automation integration: Manual adjustments are required for product changes, and lack of support for modern programmable logic controllers, motion control systems, and protocols like Modbus, PROFINET, or Ethernet/IP prevents Industry 4.0 readiness.

Why PLC Control is Essential

- Precise synchronization with encoder feedback: Advanced programmable logic controllers (PLCs) process high-speed encoder signals to synchronize the cutter with conveyor or roller speed, ensuring consistent cut-to-length accuracy in flying shear machines.

- Real-time control at variable speeds: Through high-speed processing and motion control systems, PLC automation dynamically adjusts cutter timing, maintaining precision even when production line speeds fluctuate.

- Flexible programming for diverse applications: Support for IEC 61131-3 programming languages allows engineers to configure flying shear machines for different product lengths and materials, enabling rapid recipe changes without hardware modifications.

- Automatic fault detection and safety interlocks: Integrated diagnostics, PID controllers, and fault monitoring protect motors, encoders, and blades while enabling predictive maintenance and minimizing downtime.

- Seamless integration with HMI/SCADA platforms: Provides easy setup, real-time monitoring, and seamless integration with modern automation systems, supporting efficient operation and Industry 4.0 readiness.

Overview of NX-ERA Xpress PLC

Messung’s NX-ERA Xpress PLC is a compact yet powerful controller designed for high-speed motion and precision applications. Its fast processing and real-time response make it ideal for demanding operations such as flying shear machines, cut-to-length systems and continuous production lines where accuracy and timing are critical.

Equipped with high-speed counters and encoder inputs, the NX-ERA Xpress ensures precise synchronization and minimal scrap even at variable line speeds. It integrates easily with servo drives, VFDs, HMIs and SCADA systems while supporting industrial protocols like EtherNet/IP, PROFINET, Modbus TCP, MQTT and CANopen for seamless connectivity.

With built-in PID control, real-time diagnostics and IEC 61131-3 programming through the MasterTool IEC XE platform, it combines performance, flexibility and Industry 4.0 readiness to deliver a reliable and cost-effective automation solution for OEMs and manufacturers.

Key Features for Flying Shear Applications

| Feature | Process Enhancement |

|---|---|

| High-speed encoder interface | Ensures precise material length detection, delivering superior cut-to-length accuracy even at high production speeds. |

| Advanced motion control algorithms | Synchronizes the cutter with moving material in real time, minimizing scrap and enhancing throughput in flying shear machines. |

| Real-time cut length adjustment | Enables length modifications without stopping the line, improving flexibility and reducing downtime in cut-to-length machines. |

| Integrated PID control | Provides smooth and stable motor speed regulation, ensuring consistent performance in high-speed motion control systems. |

| Fault diagnostics | Detects anomalies in motors, encoders, and blades early, enabling predictive maintenance and reducing unexpected stoppages. |

| Recipe management | Allows quick changeovers between product lengths, boosting adaptability and efficiency in batch production. |

| Industrial communication protocols | Supports Modbus, Ethernet/IP, PROFINET, and CANopen, enabling seamless integration with HMIs, drives, SCADA, and industrial automation systems. |

Benefits of Using NX-ERA Xpress PLC

- High cutting accuracy at high production speeds: Equipped with high-speed counters (HSC) and precise encoder inputs, the PLC delivers real-time synchronization between line speed and blade movement, ensuring superior cut-to-length accuracy in high-speed flying shear machines.

- Reduced wastage due to precise length control: Advanced motion control algorithms combined with auto-tuned PID controllers dynamically regulate motor speed, minimizing over-cut and under-cut errors and significantly lowering scrap in cut to length machines across rolling mills and tube mills.

- Improved machine reliability and lower maintenance costs: By replacing mechanical linkages with PLC-based digital synchronization, the system reduces backlash, vibration, and mechanical stress on blades and couplings. Built-in fault diagnostics for motors, encoders, and I/Os further enhance uptime and reduce service intervals.

- Increased production throughput with minimal downtime: The CODESYS runtime engine enables deterministic execution and fast scan cycles, while recipe management allows on-the-fly product length changes without line stoppages, improving throughput and operational efficiency.

- Scalability for small tube mills to large rolling mills: With models ranging from XP300 (basic digital I/O) to XP350 (integrated motion control with EtherCAT and CAM editor), the NX-ERA Xpress adapts to applications from compact utility machines to complex motion control systems in heavy-duty steel plants.

- Easy operator interface for real-time monitoring and control: The NX-ERA Xpress offers native connectivity for seamless integration with HMI and SCADA systems, enabling efficient operation, real-time diagnostics, and secure remote monitoring through WebServer, VPN, and firewall protection.

Conformal coating product ensures safety in harsh environments: The PLC hardware is conformal-coated to protect against dust, humidity, and temperature extremes, ensuring robust performance in demanding shop-floor conditions such as steel, aluminum, and copper processing lines.

Applications of Flying Shear with NX-ERA Xpress PLC

- Steel rolling mills for bar and rod cutting: Equipped with high-speed counters (HSC) and encoder feedback, the PLC maintains precise blade synchronization with rolling speed. This ensures consistent cut-to-length accuracy in bar and rod lines, minimizing scrap and improving yield.

- Tube and pipe manufacturing plants: Integration with servo drives and VFDs allows dynamic motion control for blades cutting at variable diameters and thicknesses. Recipe management within the programmable logic controller enables fast changeovers between pipe sizes, reducing downtime.

- Sheet cutting in continuous process lines: The NX-ERA Xpress leverages PID control and deterministic execution on the CODESYS runtime to regulate conveyor speed and cutting motion in real time. This delivers precision sheet length cutting without interrupting throughput.

- Aluminum and copper processing industries: Rugged, conformal coated PLC hardware ensures reliable operation in high-temperature and high-humidity environments. Native support for EtherNet/IP, PROFINET, Modbus TCP, and MQTT enables seamless system integration with upstream and downstream processes.

- Wire and cable cutting machines: The controller’s motion control algorithms with EtherCAT support provide real-time synchronization and cut length adjustments at high line speeds, ensuring uniform cable lengths and reducing production waste.

Conclusion

Messung’s NX-ERA Xpress PLC redefines high-speed cutting applications by delivering precise cut-to-length accuracy, advanced motion control, and intelligent synchronization. It provides robust, scalable, and reliable PLC solutions capable of handling demanding operations across industries such as steel, aluminum, copper, and wire processing, ensuring consistent performance, operational efficiency, and minimal downtime. With integrated IoT connectivity, support for EtherNet/IP, PROFINET, Modbus TCP, MQTT, and full Industry 4.0 compatibility, Messung empowers manufacturers to implement smarter, data-driven, and future-ready production lines while maintaining high operational standards.

Elevate your cutting operations and advance your production capabilities with Messung’s NX-ERA Xpress PLC. Experience greater precision, optimized productivity, and intelligent decision-making by leveraging Messung’s advanced solutions to build high-performance, digitally connected, and future-ready industrial automation systems.