Every flawless casting begins with uncompromising precision, and core shooter forging machines are the driving force behind that perfection. These specialized foundry systems are designed not only to produce sand cores that form the internal cavities of metal castings but also to handle varying core sizes and shapes with speed and repeatability. Such capabilities make core shooter forging machines critical for modern foundries striving for operational efficiency, consistent output, and superior casting performance.

Core shooter forging machines automate the process of shaping, compressing, and curing sand cores, ensuring uniformity and precision that are critical to the structural integrity and dimensional accuracy of the final casting. The quality of these sand cores directly impacts overall casting quality, making core shooter machines essential for XMindustries such as automotive, heavy engineering, and general foundries where precision and reliability are paramount. In traditional setups, manual operation of core shooting machines often leads to inconsistencies in cycle timing, pressure application, and density, resulting in higher rejection rates, production delays, and reduced operational efficiency.

Implementing industrial automation PLCs, compact PLC systems, and smart controllers transforms core shooter forging machines into highly reliable and consistent systems. These programmable logic controllers enable precise cycle control, real-time monitoring, and optimized process management. Automation minimizes human error, maintains uniform core production, and enhances overall productivity, helping foundries meet the rigorous demands of modern manufacturing while ensuring superior casting quality.

Challenges in Conventional Core Shooter Machines

When precision defines the quality of every casting, relying on manual operations carries significant risks. Traditional core shooter machines that rely on manual controls often struggle to achieve the accuracy and consistency demanded by modern industrial automation systems

Key challenges include:

- Inconsistent core quality : Variations in cycle timing, pressure, and sand compaction during manual operation lead to defects in sand cores, causing dimensional inaccuracies and higher rejection rates in castings.

- Unstable production cycles : Variations in shooting and curing parameters compromise process consistency, leading to uneven core density and reduced structural strength.

- High dependency on operators : Skilled labor is required to monitor and adjust operations, increasing the risk of human error and driving up operational costs.

- Limited process visibility : Conventional systems lack real-time monitoring and data logging, making it difficult to track performance, detect faults, or maintain uniform quality across batches.

- Reduced productivity and higher costs : Slow cycle times, frequent stoppages, and quality rejections lower output, waste resources, and increase energy consumption.

In an era where PLC automation, compact PLC systems, and smart controllers are redefining foundry efficiency, these limitations expose conventional core shooter machines to rising production risks and shrinking profit margins.

Why Automation is Essential in Core Shooter Machines

For foundries striving for unmatched precision and reliability, automating core shooter machines is key to achieving consistent casting quality and streamlined operations. Modern industrial automation PLCs enable precise control over every stage of the process, reducing variability and improving reliability.

- Consistent cycle control – Automation ensures accurate timing and pressure during shooting, curing, and ejection, producing uniform sand cores with minimal defects.

- Optimized sequence management – Each stage of the core production process is executed in the correct order, eliminating errors caused by manual intervention.

- Reduced human error – Automation decreases reliance on skilled operators, minimizing mistakes and enhancing process reliability.

- Enhanced productivity – Faster, repeatable cycles and seamless integration with smart controllers increase throughput, helping foundries meet production targets efficiently.

- Real-time monitoring and control – Automated systems provide instant visibility into operations, enabling proactive adjustments and predictive maintenance to avoid downtime.

By integrating compact PLC systems, programmable logic controllers, and intelligent controllers, foundries can overcome the limitations of manual operation while ensuring superior casting quality and higher productivity.

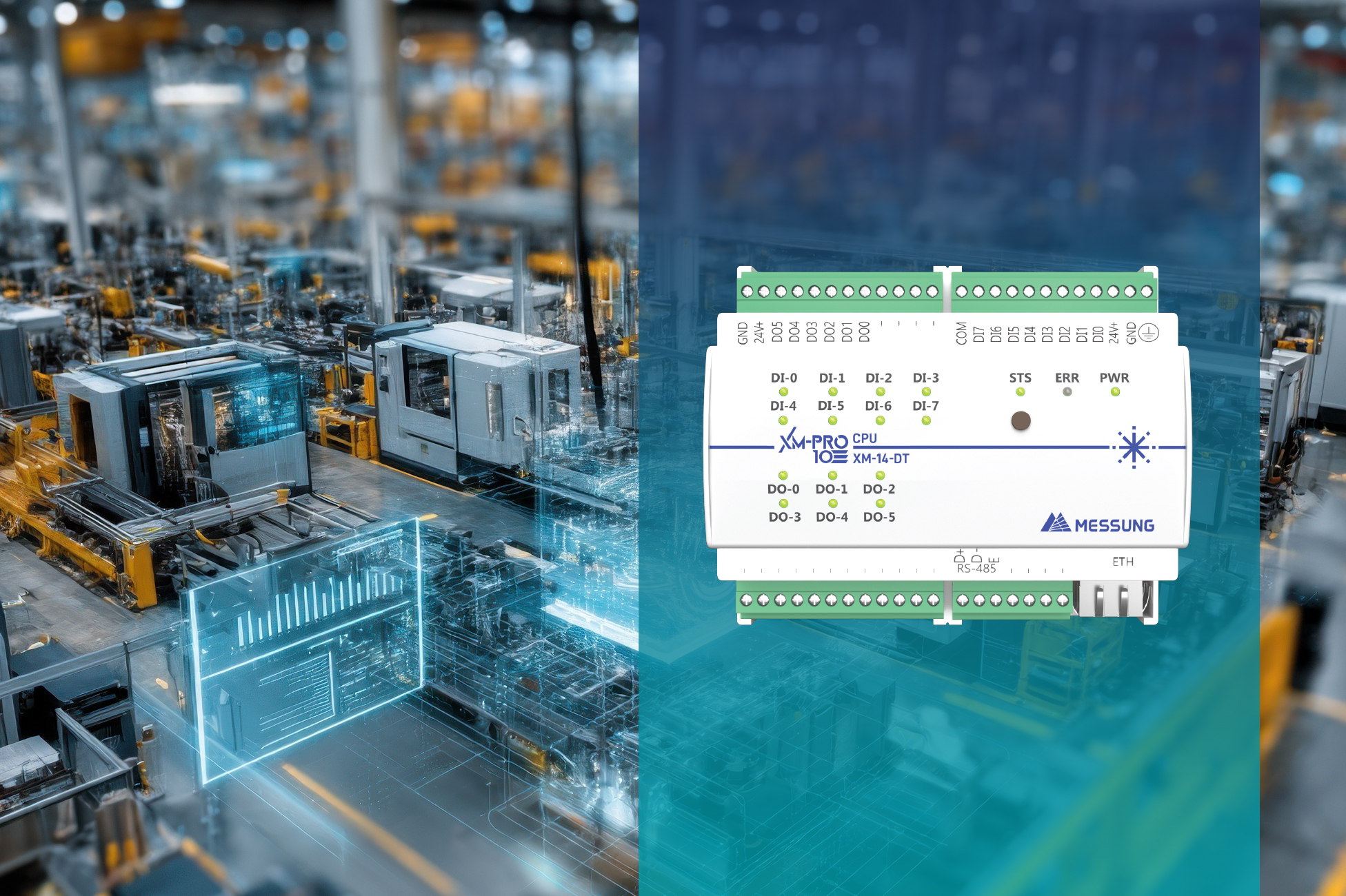

Overview of XM-PRO 10 PLC

The XM-PRO 10 PLC is a compact, high-performance industrial automation PLC designed to deliver precise control and reliable performance in demanding manufacturing environments. It supports multiple digital and analog I/Os, allowing seamless integration with sensors, actuators, and other field devices to ensure accurate and efficient operation of core shooter machines.

With high-speed processing capabilities, the XM-PRO 10 PLC executes time-critical control tasks with reliability, enabling consistent cycle timing and precise process management. The built-in PID controllers allow fine-tuned regulation of parameters such as pressure, temperature, and timing, ensuring uniform core quality in every production batch.

Advanced communication ports provide compatibility with SCADA systems and plant monitoring platforms, facilitating real-time data monitoring, diagnostics, and integration into broader industrial automation systems. Its flexible architecture and support for IEC 61131 programming standards make it scalable and adaptable, allowing foundries to expand or modify operations without compromising performance or reliability.

Key Features for Core Shooter Applications

| Feature | Description |

|---|---|

| Precise Timing Control | Ensures exact cycle durations for shooting, curing, and ejection, maintaining consistent sand core density and uniformity across all production batches. |

| Sequence Automation | Automates every stage of core production, eliminating manual errors and ensuring smooth, uninterrupted operation. |

| Sensor Integration | Interfaces with pressure, temperature, and limit sensors for real-time monitoring and precise process control. |

| Fault Diagnostics and Alerts | Detects abnormalities such as cycle interruptions or parameter deviations and triggers immediate alerts to reduce downtime. |

| Data Logging and Monitoring | Records machine cycles and performance metrics for predictive maintenance, process optimization, and informed decision-making. |

Technical Advantages of XM-PRO 10 PLC in Core Shooters

- High-Speed Response: Sub-millisecond scan times enable precise execution of time-critical processes, ensuring consistent performance in fast-paced core production cycles.

- Flexible Programming: Supports IEC 61131-3 programming standards, allowing easy customization and adaptation to diverse core shooter machine requirements.

- Expandable Architecture: The PLC can be scaled with additional I/O modules, providing flexibility to accommodate growing or evolving production needs.

- Reliable Operation: Engineered for harsh industrial environments, the XM-PRO 10 PLC ensures continuous uptime and dependable performance under demanding foundry conditions.

- Seamless Integration: Supports communication protocols such as Modbus RTU, Modbus TCP, and MQTT, enabling smooth connection with SCADA systems and plant monitoring solutions.

Benefits of Using XM-PRO 10 PLC in Core Shooter Forging Machines

- Consistent Casting Quality: Ensures uniform sand core production, reducing casting defects and improving overall product reliability.

- Reduced Machine Downtime: Automated fault detection and error handling minimize stoppages, keeping production continuous and efficient.

- Enhanced Productivity: Optimized cycle sequencing and faster operation increase throughput, enabling foundries to meet higher production targets.

- Lower Dependency on Skilled Labor: Automation reduces reliance on manual intervention, freeing operators for more strategic tasks and lowering labor costs.

- Cost Efficiency: Fewer rejections and minimized breakdowns translate to significant savings in materials, energy, and operational expenses.

Applications of Core Shooter Machines with XM-PRO 10 PLC

- Automotive Foundries: Ensures reliable production of engine blocks, gear housings, and other precision castings with uniform core shooter machine quality.

- Heavy Engineering: Supports large-scale casting operations in construction, mining, and infrastructure equipment, delivering consistent performance and reduced downtime with industrial automation PLC.

- General Foundries: Optimizes small and medium-scale foundries for better throughput, accuracy, and process efficiency using compact PLC systems and smart controllers.

- Industrial Equipment Manufacturing: Ideal for producing complex castings in agricultural machinery, pumps, and compressors where dimensional accuracy is critical with PLC automation.

- Defense and Aerospace Components: Facilitates high-precision core production for mission-critical and safety-sensitive components requiring stringent quality standards through programmable logic controllers.

Conclusion

In the evolving world of foundry operations, consistent precision and dependable performance set the standard for excellence. Integrating Messung’s XM-PRO 10 PLC with core shooter machines empowers foundries to overcome long-standing challenges of inconsistent cores, downtime, and process inefficiencies. This industrial automation PLC delivers consistent core production, real-time process control, and optimized cycle management, ensuring superior casting quality and operational efficiency.Supported by Messung’s in-house R&D and dependable after-sales service, the solution provides long-term reliability for demanding industrial environments. With its scalable architecture and robust performance, Messung’s XM-PRO 10 PLC positions forging industries to meet modern manufacturing demands with confidence and maximum uptime.

Unlock the potential of precision automation. Connect with Messung to see how our solutions ensure consistent, reliable, and high-quality textile production.