Milling machines in various types of vertical milling machines, horizontal milling machines, cnc milling machines form the backbone of modern manufacturing, enabling precise material removal and accurate shaping of components that are critical to performance, safety, and durability. From automotive engine blocks and transmission housings to aerospace structural parts, tooling fixtures, and general engineering plc components, milling operations play a decisive role in defining dimensional accuracy and surface quality. As global manufacturing standards continue to rise with advanced robotics, the expectations from milling processes have shifted significantly—from simple material removal to highly repeatable, tightly controlled, and safety-driven machining operations.

In today’s competitive manufacturing environment, traditional manual and semi-automatic milling machines increasingly struggle to meet these expectations. Tight tolerances, complex geometries, higher batch volumes, and reduced delivery timelines place immense pressure on operators and machine systems alike. Manual interventions, operator-dependent decisions, and inconsistent sequencing often lead to dimensional variations, surface finish defects, tool wear, rework, and unplanned downtime.

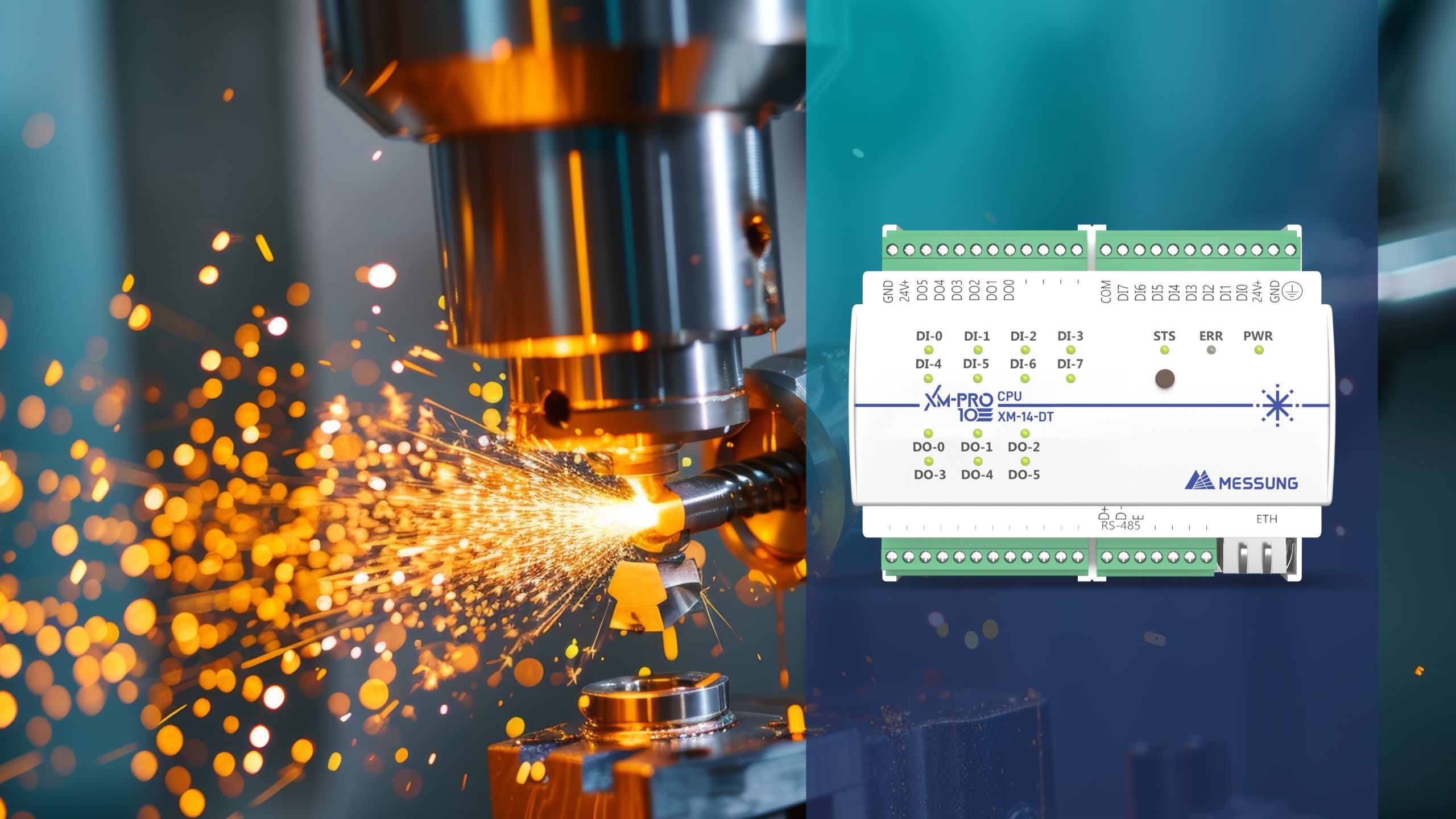

This is where a PLC-based Milling Automation System using Messung’s XMPRO-10 PLC delivers a decisive advantage. By introducing reliable programmable logic control into milling operations, manufacturers can automate critical machine functions such as spindle operation, axis sequencing, feed control, auxiliary system coordination, and safety interlocking. The result with plc control systems is a more consistent, predictable, and efficient machining process that enhances productivity while maintaining high-quality standards.

Why PLC-Based Automation Is Essential for Milling Applications

Milling is a multi-variable process that depends on precise coordination between mechanical motion, spindle dynamics, cutting parameters, and safety systems. Each machining cycle involves a series of interdependent actions—spindle start and stop, feed engagement, axis positioning, coolant activation, and tool movement. Any deviation in timing, sequencing, or execution can directly affect machining accuracy and tool life.

In manual or relay-based systems, these actions rely heavily on operator judgment and mechanical switches. While experienced operators can deliver acceptable results, consistency becomes difficult to maintain across shifts, batches, and varying production demands. Human error, fatigue, and skill dependency introduce variability that is unacceptable in modern manufacturing.

A PLC-controlled milling machine equipped with a smart controller overcomes these limitations by executing all control logic in a deterministic and programmable manner. With PLC-based automation, machining sequences are predefined, tested, and executed identically every time. This ensures stable coordination between spindle motion, feed rates, and auxiliary systems, regardless of operator or shift.

Key advantages of PLC-based milling automation include deterministic control of machining sequences, reliable synchronization of spindle, feed, and safety systems, reduced dependency on operator skill, and consistent machining outcomes across batches. At the core of this automation framework in the electrical control panel, the XMPRO-10 PLC ensures predictable and repeatable execution of all milling machine control logic.

XMPRO-10 PLC – Robust Control Platform for Milling Machines

Messung’s XMPRO-10 PLC is purpose-built for industrial automation solutions where real-time responsiveness, operational reliability, and long-term stability are non-negotiable. In milling environments, where precise timing between mechanical actions is critical, the PLC serves as the central intelligence that governs machine behaviour.

As a reputed industrial automation company, Messung team offers innovative and effective automation solutions. One of the key strengths of the XMPRO-10 PLC lies in its deterministic processing capability. Milling cycles often involve rapid transitions between spindle states, feed engagement, and axis movement. Stable PLC scan times ensure that these transitions occur exactly as programmed, without timing mismatches or delays that could lead to tool chatter, uneven cuts, or dimensional inaccuracies.

The PLC handles essential milling functions such as spindle ON/OFF control, direction selection, feed motor sequencing, and axis interlocking. Each action is executed based on predefined logic conditions, ensuring that mechanical movements only occur when safety and positional criteria are satisfied. This eliminates the risk of premature movement or unsafe machine states.

In addition to precise sequencing, the XMPRO-10 PLC offers a flexible control architecture that supports a wide range of digital I/O configurations. This allows seamless integration of limit switches, home sensors, tool position feedback devices, safety doors, and emergency stop circuits. As a result, the PLC-based solution is suitable for conventional milling machines, semi-automatic setups, and special-purpose milling equipment used in custom manufacturing environments.

Milling Automation System – Technical Process Overview

A PLC-driven milling automation system transforms conventional machine operation into a structured, repeatable, and safe process. Once the automation logic is implemented, the milling machine operates as a coordinated system rather than a collection of independent mechanical actions.

The automated milling cycle begins with programmed spindle control. The PLC initiates spindle start-up only after verifying that all safety conditions are met, such as door closure, axis home confirmation, and emergency stop reset. Direction and speed commands are issued in accordance with the machining requirement, ensuring stable cutting conditions from the start of the cycle.

Feed engagement and disengagement are also managed automatically. The PLC controls feed motors to initiate cutting motion at the correct moment, preventing tool shock and ensuring smooth entry into the workpiece. During roughing and finishing operations, the PLC enforces defined sequencing logic, allowing controlled transitions between machining stages.

Safety and interlocking logic form a critical part of the automation architecture. Door and guard interlocks prevent machine operation under unsafe conditions, while emergency stop integration ensures immediate shutdown during abnormal events. Axis limit protection prevents over-travel and mechanical damage, safeguarding both machine components and cutting tools.

By eliminating manual intervention during critical stages, the PLC ensures identical execution of every machining cycle. This repeatability significantly reduces human error, improves dimensional consistency, and enhances surface finish quality across all produced parts.

Applications of PLC-Controlled Milling Machines

PLC-based milling automation finds application across a wide spectrum of manufacturing industries, each with its own precision and productivity requirements.

In automotive component manufacturing, PLC-controlled milling machines are used for high-accuracy machining of engine parts, brackets, housings, and transmission components. Consistent machining quality is essential in automotive production, where even minor deviations can affect assembly fit and performance.

Tool and die manufacturing rely heavily on precision milling for producing molds, fixtures, and cutting tools. Here, repeatable machining accuracy and surface finish are critical, making PLC automation an effective solution for maintaining quality while improving throughput.

In the aerospace and heavy engineering sectors, milling machines are used to process high-strength alloys and structural components. These materials require controlled machining conditions to prevent tool wear and material distortion. PLC-based automation ensures stable feed and spindle coordination, reducing risk and improving process reliability.

General engineering and OEM production environments also benefit from PLC-controlled milling systems, particularly in batch and repetitive machining applications. Automation allows manufacturers to maintain consistency while adapting to varying production volumes and component designs.

Key Technical and Operational Benefits

One of the most significant advantages of PLC-based milling automation is improved machining accuracy. By maintaining consistent feed rates, spindle speeds, and sequencing logic, the system minimizes dimensional deviation and ensures superior surface finish. Reduced tool stress also extends tool life, lowering tooling costs over time.

Productivity gains are another major benefit. Automated machining cycles reduce setup time, minimize idle periods, and enable faster changeovers. Operators can focus on loading, unloading, and inspection rather than manual control, increasing overall machine utilization.

Machine safety is substantially enhanced through PLC-based interlocks and protection logic. By continuously monitoring safety inputs and enforcing operational constraints, the system reduces the risk of crashes, tool breakage, and operator injury. This not only protects equipment but also fosters a safer working environment.

From a maintenance perspective, the PLC-based control system offers long-term reliability and ease of troubleshooting. A simple and structured PLC architecture allows maintenance teams to quickly identify faults, reducing downtime. Additionally, the system can be easily upgraded or customized to accommodate future production requirements.

A Cost-Effective and Scalable Milling Automation Solution

The Milling Automation System using Messung XMPRO-10 PLC represents a practical and economical approach to modernizing milling operations. It delivers reliable PLC-based machine control without the complexity and cost associated with full CNC systems.

Manufacturers benefit from deterministic sequencing tailored specifically for milling applications, ensuring consistent machining results. The scalable architecture allows additional features such as enhanced safety functions, auxiliary automation, or process monitoring to be integrated as production needs evolve.

This solution is particularly well-suited for OEMs, system integrators, and manufacturing plants seeking to enhance machining performance while maintaining cost control. It provides a balanced pathway between manual machining and advanced CNC automation, making it accessible to a wide range of industrial users.

Conclusion

As machining requirements continue to evolve, milling operations must deliver higher levels of consistency, precision, and safety. Manual and semi-automatic systems are increasingly challenged by these demands, making automation a strategic necessity rather than an optional upgrade.

By implementing a PLC-based milling automation solution using Messung’s XMPRO-10 PLC, manufacturers can achieve repeatable machining accuracy, improved productivity, and reliable machine performance. The system ensures precise sequencing, enhanced safety, and long-term operational stability.

This approach effectively bridges the gap between traditional machining and full CNC systems, offering a robust, scalable, and cost-effective solution for modern milling applications. In an era where quality, efficiency, and reliability define competitiveness, PLC-driven milling automation provides a strong foundation for sustainable manufacturing excellence.