Automated Guided Vehicles (AGVs) have become the backbone of modern smart factories, warehouses, and intralogistics environments. As industries shift toward higher productivity, reduced manual dependency, and safer material handling, AGVs provide efficient, safe, and repeatable material movement across production floors and storage facilities. From transporting raw materials to delivering finished goods, AGVs operate continuously in dynamic industrial environments where precision and reliability are critical.

AGV applications demand fast control response, reliable sensor integration, compact hardware architecture, and cost-effective implementation—particularly for small and mid-size machines. A robust PLC automation platform is essential to ensure deterministic behaviour, safe motion control, and real-time decision-making.

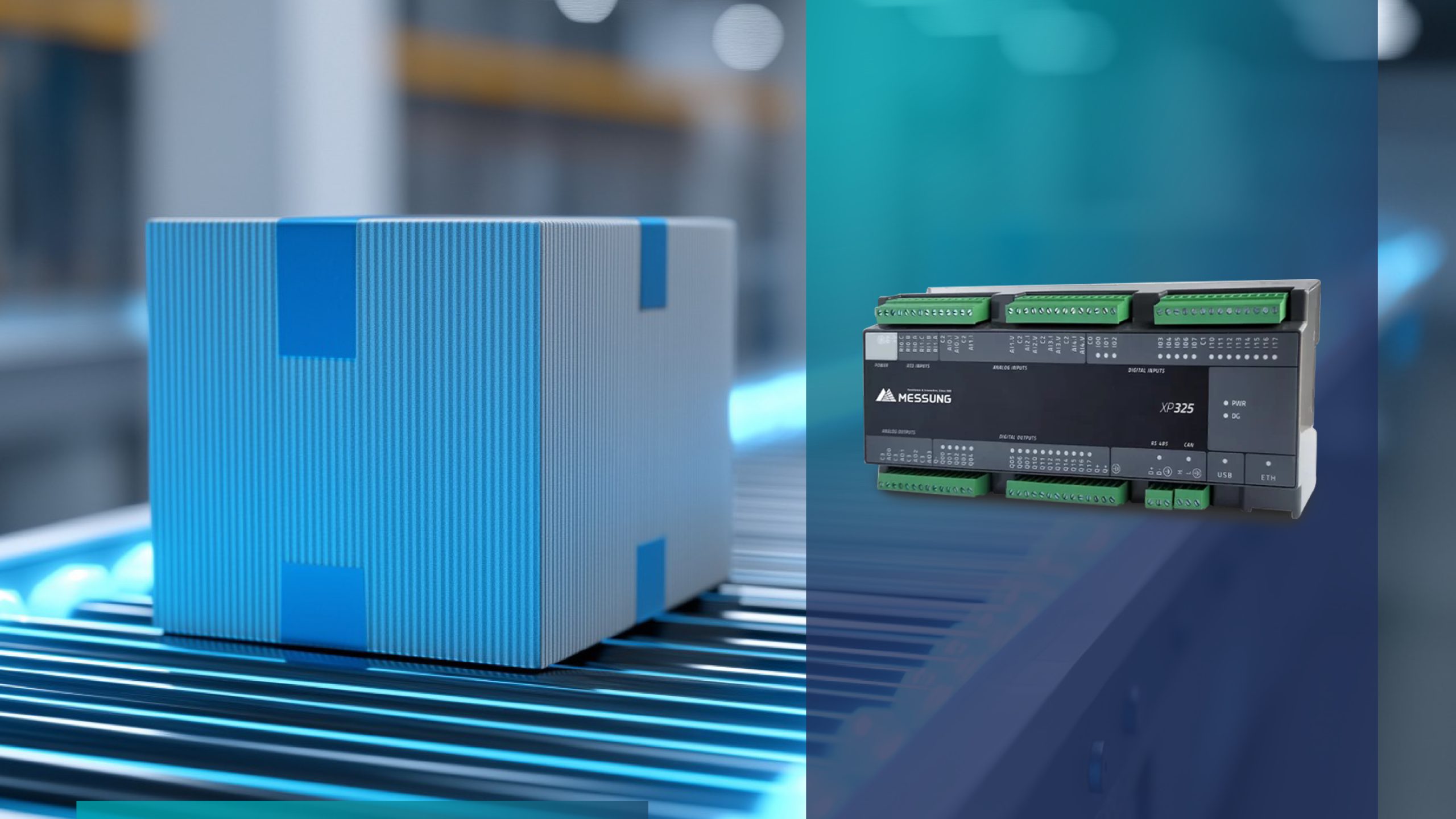

Messung’s NX-ERA XPRESS XP325 PLC, part of the NX-ERA Xpress series, is a compact, cost-effective, and feature-rich controller designed specifically for such demanding applications. Developed as an advanced CODESYS PLC, the XPRESS XP325 enables precise motion control, real-time safety handling, flexible analog processing, and intelligent diagnostics—all within a compact footprint. It offers the performance of an advanced industrial PLC while maintaining the affordability of a low cost PLC in India for AGV automation.

Why PLC-Based AGV Automation Is Critical

AGVs operate in shared environments with human operators, forklifts, conveyors, and other automation systems. Timing, safety, and accuracy are non-negotiable. Manual control systems or low-end controllers often fail to provide deterministic execution, leading to unpredictable movement, unsafe conditions, or downtime.

A well-designed PLC control system ensures:

● Deterministic logic execution for accurate navigation

● Real-time processing of sensor and safety signals

● Stable motor and drive control

● High system reliability with minimal downtime

● Seamless integration with plant-level Automation systems

Unlike conventional controllers, modern Programmable logic controllers are built for industrial durability and real-time performance. A PLC for automation ensures consistent scan cycles, predictable response times, and high fault tolerance—essential characteristics for AGV systems operating 24/7.

The NX-ERA XPRESS XP325 bridges the gap between performance and cost. It functions as a powerful compact PLC, offering advanced capabilities typically associated with large Modular PLC platforms, while maintaining the footprint of a mini PLC or Micro PLC solution.

NX-ERA XPRESS XP325 – Compact Control Core for AGV Systems

The NX-ERA XPRESS XP325 is engineered for automation applications requiring high functionality in a compact package. It is particularly suited for AGV manufacturers and system integrators looking for a small PLC with advanced features and scalability.

As one of the innovative solutions offered by Messung, the NX-ERA XPRESS XP325 represents the evolution of modern PLC for automation in India.

High-Performance Processing on CODESYS Platform

The controller is built on the globally recognized CODESYS technology platform, making it a highly capable CODESYS PLC for AGV applications.

Key features include:

- Deterministic program execution

- Structured programming capability

- Advanced diagnostics and debugging tools

- Scalable application development

- Support for complex motion and safety logic

This ensures smooth AGV movement, accurate stopping, and predictable behavior under varying load conditions. Deterministic logic is crucial in PLC motion control, especially when AGVs navigate tight aisles, docking stations, and dynamic pathways.

For system integrators seeking flexibility, the XPRESS XP325 functions both as a compact PLC and as a scalable automation core within larger distributed systems.

Advanced Analog and Temperature Input Capability

AGVs are sensor-rich systems. They rely on proximity sensors, load cells, encoders, battery temperature sensors, and environmental monitors to operate safely and efficiently. Many entry-level controllers lack integrated analog capabilities, forcing designers to add external modules—raising cost and complexity.

The NX-ERA XPRESS XP325 stands out as a feature-rich industrial PLC by offering built-in analog and temperature inputs.

Built-in Analog Inputs

- 4 Analog Inputs configurable for Voltage or Current

- 12-bit resolution for accurate sensor data acquisition

- Direct support for:

- Distance and proximity sensors

- Load and pressure sensors

- Speed feedback transducers

- Analog position references

High-resolution analog processing enhances precision in AGV navigation and load handling. In material transport applications, even minor inaccuracies can cause misalignment or unsafe movement. A 12-bit resolution ensures fine-grained control, essential for reliable PLC automation.

RTD Temperature Inputs

- 2 Built-in RTD inputs

- Direct temperature measurement without external modules

- Suitable for:

- Battery temperature monitoring

- Motor and drive thermal supervision

- Enclosure environmental monitoring

Thermal monitoring is critical in battery-powered AGVs. Overheating batteries or motors can cause operational failures or safety hazards. With integrated RTD inputs, the XPRESS XP325 eliminates the need for additional expansion modules, reinforcing its identity as a low cost PLC solution without compromising performance.

Built-in Analog Outputs for Precise Control

The XPRESS XP325 includes:

- 2 Analog Outputs (12-bit resolution)

These outputs enable precise control of:

- Motor speed references

- Drive setpoints

- Hydraulic lift positioning

- Actuator modulation

In AGVs equipped with lift mechanisms or precision docking functions, smooth analog output control is essential. Integrated analog outputs reduce wiring complexity, panel space, and hardware cost—making the controller an efficient mini PLC for compact AGV systems.

By integrating inputs and outputs within a single programmable controller, system architects can reduce total cost of ownership and improve system reliability.

PLC Motion Control in AGV Systems

Motion control is the heart of AGV functionality. Whether line-following, magnetic strip guidance, or sensor-based navigation, AGVs must accelerate, decelerate, turn, and stop with precision.

The NX-ERA XPRESS XP325 supports advanced PLC motion control, enabling:

- Controlled ramp-up and ramp-down

- Speed regulation under varying loads

- Encoder feedback processing

- Synchronization with conveyors and workstations

Unlike simple relay-based systems, a true PLC control system ensures stable and repeatable movement profiles. For AGVs operating in narrow aisles or high-density warehouses, motion accuracy directly impacts safety and productivity.

PLC PID Control for Intelligent AGV Operation

Dynamic industrial environments require adaptive control strategies. The XPRESS XP325 includes an auto-tune PID block that enhances control precision.

PLC PID Control Applications in AGVs

- Speed control of traction motors

- Flow or pressure control in hydraulic lifts

- Temperature regulation for battery cooling

- Steering angle correction

The built-in auto-tuning simplifies commissioning. Instead of manually adjusting parameters, engineers can rely on intelligent tuning to achieve stable performance quickly. This reduces installation time and enhances repeatability across multiple AGV units.

In modern PLC automation, integrated PLC PID control capabilities are essential for dynamic systems requiring stable closed-loop operation.

Safety and Sensor Integration

AGVs operate alongside human workers. Safety integration is therefore mandatory.

The NX-ERA XPRESS XP325 interfaces seamlessly with:

- Obstacle detection sensors

- Emergency stop circuits

- Encoders and feedback devices

- Battery management systems

- Safety relays

Real-time processing ensures immediate response to unsafe conditions. Deterministic execution provided by a robust industrial PLC architecture ensures reliable safety performance.

For manufacturers seeking compliance and reliability, selecting a trusted partner among PLC manufacturers in India is crucial. The XPRESS XP325 delivers international-grade performance while supporting localized industrial needs.

Integration with IIOT and Smart Factory Systems

Modern AGVs are no longer isolated machines. They are integrated nodes within Industry 4.0 ecosystems. Connectivity with IIOT platforms enables monitoring, predictive maintenance, and performance analytics.

As a CODESYS-based platform, the XPRESS XP325 supports integration with IIOT and IOT infrastructures, allowing:

- Remote diagnostics

- Fleet monitoring

- Data logging and analytics

- Integration with MES and ERP systems

- Predictive maintenance insights

By embedding AGVs within connected Automation systems, manufacturers can optimize material flow, reduce downtime, and enhance visibility across operations.

Automated AGV Functional Overview

Navigation and Motion Control

- PLC-based route logic and path selection

- Controlled acceleration and deceleration

- Smooth stopping at stations

- Docking and alignment algorithms

- Error detection and recovery logic

The deterministic execution of the PLC control system ensures consistent navigation performance across varying industrial conditions.

Load Handling Automation

- Automatic pick-and-place sequencing

- Interlocking with conveyors and robotic cells

- Lift mechanism control

- Overload detection and alarm generation

- HMI-based diagnostics and alerts

By combining motion, analog processing, and PID control, the XPRESS XP325 delivers a complete PLC for automation solution within a compact form factor.

Compact PLC Advantage for AGV Manufacturers

AGV designers prioritize space optimization and cost efficiency. A bulky Modular PLC may offer scalability but often increases system footprint and cost.

The NX-ERA XPRESS XP325 provides:

- Compact size suitable for onboard installation

- Reduced panel wiring

- Lower hardware cost

- Simplified maintenance

- High performance comparable to larger systems

It serves as an advanced compact PLC, a capable Micro PLC, and an economical low cost PLC in India—all in one solution.

Key Technical and Operational Benefits

- Compact and cost-effective PLC for AGV systems

- Built-in analog and RTD inputs reduce external modules

- Accurate 12-bit resolution for precise control

- Faster commissioning using auto-tune PID

- Advanced PLC motion control capability

- Integrated PLC PID control for stable operations

- IIOT-ready architecture for smart factories

- High reliability for continuous industrial operation

- Reduced wiring and panel space requirements

- Scalable architecture for future expansion

Why It Matters for Indian Automation Ecosystem

As manufacturing in India accelerates toward smart factory adoption, demand for reliable and economical automation solutions is increasing. AGV adoption is expanding across automotive, pharmaceuticals, FMCG, and warehousing sectors.

Choosing a solution from experienced PLC manufacturers in India ensures local support, faster deployment, and application-specific customization. The NX-ERA XPRESS XP325 combines global CODESYS standards with localized industrial expertise—making it a strategic choice for Indian AGV manufacturers.

It demonstrates how a thoughtfully designed programmable controller can bridge affordability and advanced functionality, enabling broader adoption of intelligent AGV systems.

Conclusion

AGV automation requires a controller that is compact, powerful, intelligent, and flexible. The NX-ERA XPRESS XP325 PLC delivers advanced analog processing, temperature measurement, PLC motion control, and PLC PID control on a robust CODESYS platform—making it an ideal choice for AGV applications in small and mid-size machines.

As industries continue to modernize, demand for scalable and cost-effective PLC automation solutions will only grow. The XPRESS 325 stands out as a high-performance compact PLC, combining the functionality of larger Modular PLC systems with the efficiency of a mini PLC and the affordability of a low cost PLC in India.

For AGV manufacturers and system integrators seeking reliability, performance, and future-ready connectivity through IIOT and IOT integration, the NX-ERA XPRESS XP325 provides a strong foundation for next-generation Automation systems—empowering intelligent, safe, and efficient material movement across smart industrial environments.