Modern manufacturing depends heavily on the quality and consistency of heat-treated components. Whether it is automotive gears, aerospace turbine blades, heavy engineering shafts, or precision tooling, heat treatment determines the final metallurgical properties that define strength, hardness, ductility, and fatigue resistance. In this environment, Intelligent Heat Treatment Furnace Automation with Precision PLC Control: Powered by XMPRO-10 Series PLC with Expansion modules represents a significant step forward in how industries achieve accurate, repeatable, and safe thermal processing.

Heat treatment furnaces are not simply heaters. They are precision thermal systems that must execute highly controlled temperature ramps, soak times, and cooling cycles according to strict metallurgical recipes. Any deviation—whether due to temperature overshoot, uneven heating, incorrect soak duration, or poor cooling control—can lead to microstructural defects, part distortion, or inconsistent mechanical properties. These defects directly translate into higher scrap rates, customer complaints, and reduced product life.

The Vital Solution

Traditionally, many furnaces were operated using manual control panels, thermostats, or relay-based logic. While such systems may work for basic operations, they struggle to deliver the precision, traceability, and safety demanded by modern industrial standards. This is where PLC-based automation becomes indispensable. By using Messung’s XMPRO-10 PLC with intelligent I/O expansion and HMI-driven control, manufacturers can transform conventional furnaces into smart, automated, and highly reliable thermal processing systems. In a heat treatment process, Modbus is primarily used with a PLC as the communication backbone to monitor and control critical variables like temperature, pressure, and gas flow, and to integrate various field devices with a central control system (HMI/ SCADA). Its simplicity and widespread support make it ideal for gathering real-time data from diverse equipment.

Why PLC-Based Heat Treatment Furnace Automation Is Essential

Heat treatment operations such as annealing, hardening, tempering, carburizing, and normalizing require tightly controlled temperature profiles. These profiles are often defined by standards such as AMS, ASTM, ISO, or customer-specific metallurgical specifications. Manual adjustments or relay logic cannot guarantee the consistency needed to meet these standards across hundreds or thousands of production cycles.

The Automation Boost

A PLC-controlled heat treatment furnace provides a deterministic, programmable, and data-driven way to manage these critical processes. With PLC automation, every stage of the thermal cycle—from preheating to soaking and controlled cooling—is governed by precise logic rather than human judgment. This ensures that each batch of components is processed under identical conditions.

By implementing Intelligent Heat Treatment Furnace Automation with Precision PLC Control: Powered by XMPRO-10 Series PLC with Expansion modules, manufacturers gain the ability to standardize heat treatment recipes, eliminate variability between shifts, and create traceable digital records of every cycle. This is particularly valuable for industries like aerospace and automotive, where quality audits and compliance requirements are extremely strict.

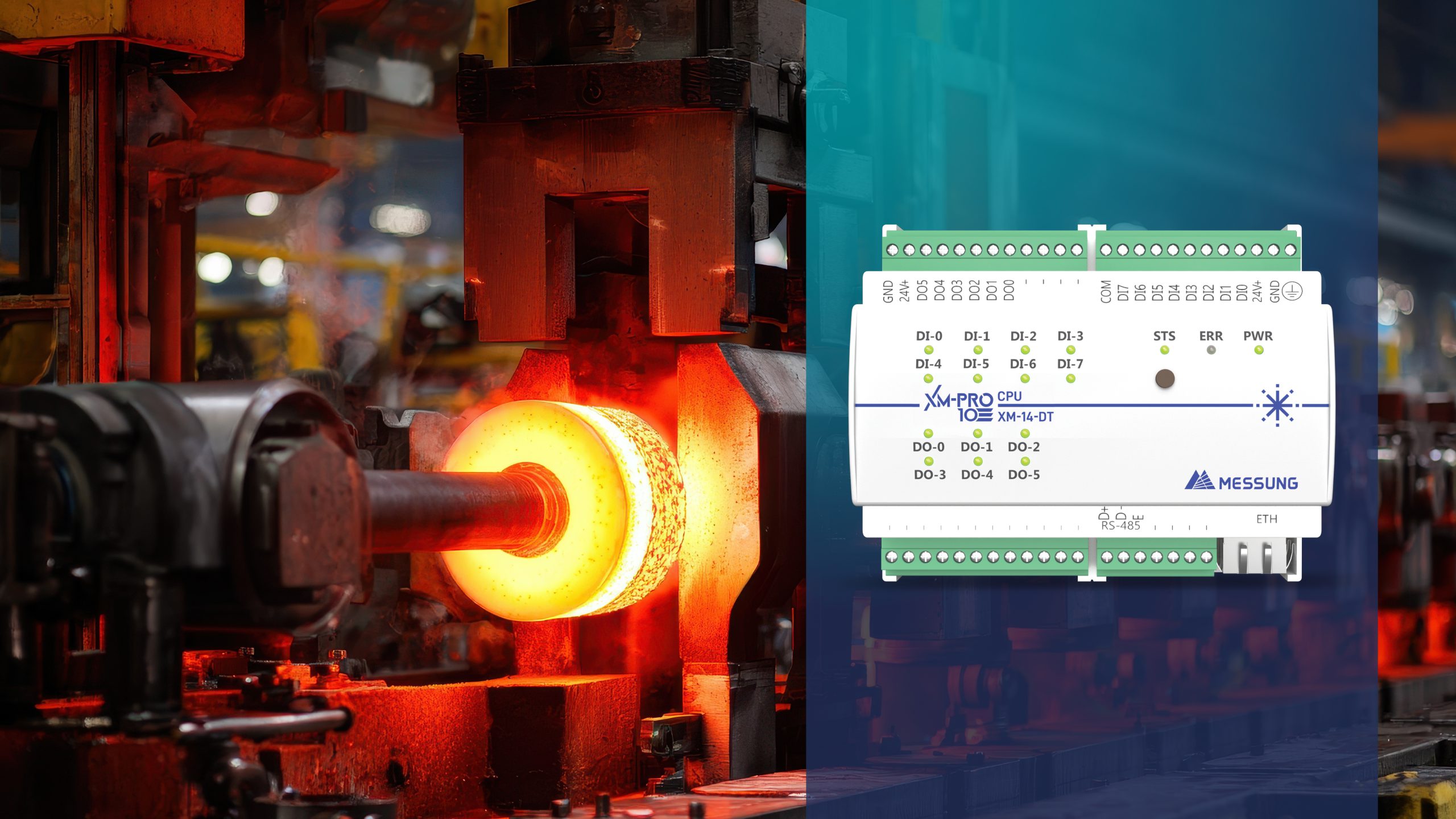

XM PRO-10 PLC – The Reliable Control Core for Thermal Processing

At the heart of this automation architecture is Messung’s XMPRO-10 PLC. Designed for industrial control applications, this PLC offers high-speed processing, stable scan times, and robust communication capabilities that are essential for controlling dynamic thermal processes.

Heat treatment furnaces operate under conditions where even a few degrees of temperature deviation can have serious consequences. The XMPRO-10 PLC ensures that control logic for heating elements, temperature controllers, fans, and dampers is executed in a deterministic manner. This prevents lag, timing errors, and uncontrolled switching that could otherwise lead to overshoot or unstable furnace behaviour.

The PLC continuously reads temperature feedback, evaluates control logic, and updates outputs in real time. This closed-loop control ensures that furnace temperature follows the programmed profile precisely, regardless of load variations or external disturbances.

HMI Integration for Intuitive Furnace Operation

An intelligent furnace is not just about control—it is also about visibility and usability. The Human-Machine Interface (HMI) integrated with the XMPRO-10 PLC allows operators to interact with the furnace in a simple, safe, and highly intuitive way.

Through the HMI, operators can select heat treatment recipes, set temperature setpoints, define soak durations, and monitor the progress of each cycle. Real-time displays show furnace temperature, heating status, alarms, and system diagnostics. This transparency reduces the chances of operator error and allows maintenance personnel to quickly identify and resolve issues.

In Intelligent Heat Treatment Furnace Automation with Precision PLC Control: Powered by XMPRO-10 Series PLC with Expansion modules, the HMI becomes a central tool in robotics for ensuring both productivity and safety. It replaces guesswork with data-driven decision-making.

XM Series Expansion Modules – Scalable I/O Architecture

Heat treatment furnaces are complex systems that require multiple digital and analog signals to operate safely and accurately. These process controllers include temperature sensors, door switches, safety interlocks, fan feedback, heating element contactors, and exhaust dampers. Messung’s XM series expansion modules provide the scalable I/O architecture needed to handle these requirements.

- XMDI8 – Digital Input Expansion

The XMDI8 module allows the PLC to receive multiple digital input signals from critical furnace components. These include door limit switches that ensure the furnace cannot operate when the door is open, emergency stop circuits that allow immediate shutdown, and fan feedback signals that confirm proper airflow. By monitoring these inputs continuously, the PLC can enforce safety interlocks and prevent hazardous operating conditions.

- XMDO6T – Digital Output Expansion

The XMDO6T module provides transistor-based digital outputs for controlling heating contactors, solid-state relays, cooling fans, and exhaust dampers. These fast and reliable outputs ensure precise switching of high-power devices, allowing the furnace to respond instantly to temperature changes or safety events.

With a total of 30 I/O points, the closed loop control system provides a balanced and future-ready architecture. This allows additional zones, sensors, or actuators to be added without redesigning the entire control system, making it ideal for expanding production needs.

Automated Heat Treatment Furnace – Technical Process Overview

A modern heat treatment furnace controlled by the XMPRO-10 PLC operates through a series of carefully orchestrated steps. Each step is governed by programmable logic and sensor feedback, ensuring consistent and accurate results.

Precision Control of Heating Cycles

The PLC manages the heating elements in each zone to ensure uniform temperature distribution. The smart controller controls ramp-up rates to avoid thermal shock and ramp-down rates to prevent material stress. This level of precision is critical for maintaining dimensional stability and microstructural integrity in heat-treated parts.

Fully Automated Furnace Operation

Once a recipe is selected on the HMI, the modular PLC automatically executes the entire cycle. It starts the heating phase, maintains the soak temperature for the required duration, and then initiates controlled cooling. During the process, it continuously monitors safety conditions and triggers alarms if any abnormal situation is detected.

Recipe-Based Operation

Multiple heat treatment recipes can be stored in the PLC and HMI. This allows quick changeover between different processes such as annealing, hardening, and tempering. Each recipe ensures that the same temperature profile is applied every time, regardless of the operator or shift.

A modern heat treatment furnace controlled by the XMPRO-10 PLC operates through a series of carefully orchestrated steps. Each step is governed by programmable logic and sensor feedback, ensuring consistent and accurate results.

Industrial Applications of Heat Treatment Furnace Automation

The versatility of Intelligent Heat Treatment Furnace Automation with Precision PLC Control: Powered by XMPRO-10 Series PLC with Expansion modules makes it suitable for a wide range of industries.

In the automotive sector, it ensures consistent hardening of gears, shafts, and bearings. In metallurgy and foundries, it provides controlled thermal processing of castings and forgings. Aerospace manufacturers rely on it to meet stringent specifications for high-performance alloys. Tool and die makers use it to achieve precise hardness and toughness in molds and cutting tools.

Key Technical and Operational Benefits

One of the most important advantages of PLC-based furnace automation is consistent metallurgical quality. By eliminating temperature fluctuations and timing errors, the system ensures uniform material properties across all parts.

Process efficiency also improves significantly. Automated cycles reduce operator dependency, increase throughput, and minimize downtime. Operators can focus on loading and unloading rather than constantly adjusting controls.

Safety is another major benefit. PLC-based interlocks, alarms, and emergency shutdown logic protect both equipment and personnel from hazardous conditions.

The modular design of the Scada system ensures easy maintenance and future scalability, making it a long-term investment rather than a short-term fix.

A Robust and Scalable Furnace Automation Architecture

The architecture built around the XMPRO-10 PLC, XMDI8 and XMDO6T modules, and HMI delivers deterministic control, intuitive operation, and reliable performance. It supports safe, repeatable, and efficient heat treatment across a wide range of industrial environments.

Future-ready Manufacturing

Heat treatment is one of the most critical processes in energy management systems, manufacturing, and it leaves no room for error. By adopting Intelligent Heat Treatment Furnace Automation with Precision PLC Control: Powered by XMPRO-10 Series PLC with Expansion modules, manufacturers can achieve the precision, repeatability, and safety required in automation systems of today’s competitive industrial landscape.

This PLC-based solution not only improves metallurgical quality and process efficiency but also lays the foundation for smarter, data-driven process automation and manufacturing. As industries move toward higher automation systems and tighter quality control, intelligent furnace automation becomes not just an advantage—but a necessity.